Hog Slat Showcases European Equipment at EuroTier

GLOBAL - Having been around Hog Slat for 20+ years, I believe one of our biggest strengths comes from the company’s ability to take its proven equipment designs and adapt to local production methods, writes Hog Slat's Scott Bauck.

Similar Situation Developing in EU

Hog Slat’s display at EuroTier showcased a new line of steel equipment tailored to the European swine market. It’s a different type of equipment than you would see Hog Slat display at the World Pork Expo.

The first thing that comes to eye is the hot-dipped galvanized finish vs. the painted finish most common in the US market. Interior space is more confined, and the building layouts reflect in equipment design. And, of course, EU regulations are followed regarding square footage allowed, penning and flooring design.

Breeding Stall

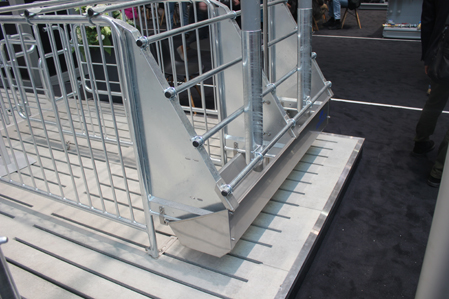

The Breeding stall features a split “saloon-style” back door. The split gate allows the operator to enter the stall while the closed section prevents the sow from backing out. The gate is designed to operated with only one hand allowing the technician to carry a preg-checker or AI equipment in the other.

Watch a short Video of the saloon doors.

European concrete slats tend to have less open area than slats in the US due to welfare regulations. Stainless steel legs rotate to allow placement of an anchor in a slat opening. A set bolt is tightened to secure the leg to the stall side. Three top and four front bars attached to the stall sides with clamps, making it easier to get a straight installation without drilling or welding.

The stainless steel feed trough will outlast composite or concrete troughs. Because sows can lie with their heads under the raised trough, the overall length can be reduced to 1.8 meters and still meet EU regulations requiring a stall to be 2 meters long.

International Crate

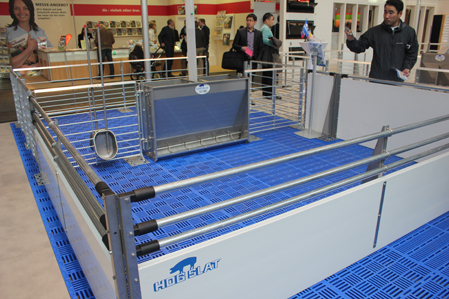

A typical pen layout will have farrowing stalls facing out against the room walls with only a center alleyway.

The combination feed and water trough is raised to allow the sow more effective stall length. Many producers choose to install the SowMAX (read more…) and fill with an automatic auger or chain disk system as hand feeding is difficult without a front feeding alley.

.jpg)

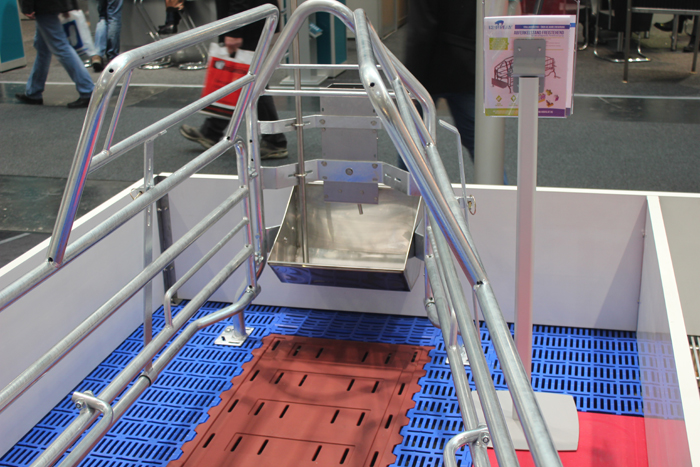

To load the crates the rear creep panel is opened, the rear gate unfastened and the movable side panel is slid to its open position. After the sow moves into stall, the operator adjusts the movable side to the size of the sow and selects one of the holes in the rear gate to hold it in place. The operator then adjusts the bottom bow bar for large or small sows. The bow bars also include anti-crushing bars to reduce pig mortality.

Hog Slat displayed its plastic flooring and with interlocking cast center sections for farrowing. Optional types of flooring sections, including red heating sections, allow producers to design a custom floor. Creep areas are larger than typically used in the U.S. The EuroTier floor measured 1.8 meters (5.9′) wide by 2.4 meters (7.87′) long.

Hog Slat also featured traditional style European penning with PVC planking on the bottom and galvanized pipes fastened to formed stainless steel posts. Notice the plastic fasteners at the end of the pipes, after the pipes are cut to length the plastic ends are forced onto the pipe and bolted into place. U.S. style horizontal penning is also finding some favor with some European producers as it is more cost effective and allows for better ventilation.

Going forward, you will see a constant blend of American and European concepts reflected in the equipment Hog Slat builds for Europe. Hog Slat’s manufacturing, sourcing and distribution expertise will lower the final cost to the producers without sacrificing quality.

US concepts in ventilation (tunnel), feeding (SowMAX), and finishing equipment (open horizontal penning) will gain acceptance with European producers looking for maximum efficiencies in producing pork.

See more housing options at HogSlat.com.

To read more about SowMAX interest at EuroTier, click here.