To Protect or Not to Protect? That is the Question

CANADA - Organic acids have been used in pig production for more than 40 years but it became a common practice in the eighties, writes Robert Gauthier, D.M.V., ACPV from Jefo.Organic Acids in Swine Production

Today organic acids are still the spearhead of alternative products used in piglets at weaning time and also in sows to reduce pathogenic bacteria excretion and help control urinary infections and vaginal discharge. Organic acids are used with classical antimicrobials or replacing them as growth promoters. The majority of the research was done during the late eighties and the nineties, following closely the discoveries on their mode of action, mostly generated by the food preservation industry. From using single acids at high dosage in the early eighties, products evolved to mixing different acids and taking into account the physiology of the digestive tract of pigs. Also in the late nineties, a new technology changed the way of using organic acids in pig production, the microencapsulation.

Excellent and thorough reviews on organic acids in pig production have been done over the years (Canibe, Partanen, Mroz, Kim, etc.), covering all organic acids, their antimicrobial properties and their main applications. Unfortunately most of the published work covers single acids, rarely blends of different acids as it is used nowadays and very rarely the use of the microencapsulation technology with organic acids. The Danish Pig Production Association in their report #778 states that free acids should be used at 1% or more in the feed to observe a positive effect.

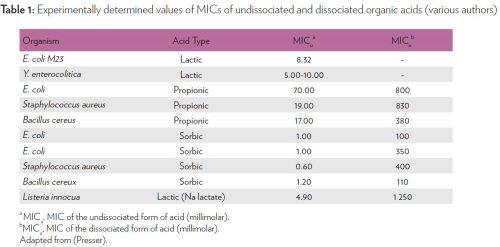

There is a consensus on the antibacterial mode of action of organic acids, the un-dissociated form of organic acids can penetrate passively through the bacteria cell membrane and dissociate inside the bacteria where the pH is near neutrality, this pH exceeding the pKa (constant of dissociation) of organic acids. Now we know that un-dissociated organic acids are much more potent to kill bacteria than their dissociated form (Presser table), in general, 10 to 100 times. Among the “pH sensitive” bacteria we have E. coli, Salmonella, Campylobacter, Clostridium. The efficacy of organic acids is independent of the gastrointestinal pH and very few research works have been able to show any effect of organic acids on the gastro intestinal (GIT) pH (even at high inclusion rate), the high acid binding capacity of the feed and the physiological response of the pig to acids maintain the GIT homeostasis. To be efficacious in piglets at weaning time, organic acids have to be used in feeds with a reduced acid binding capacity and of high digestibility. Organic acids cannot cross the proximal part of the digestive system without being dissociated and losing most of their antibacterial capacity.

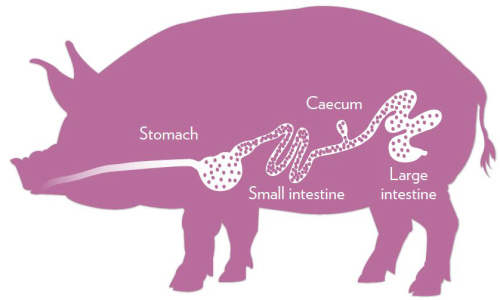

For this reason, a microencapsulation (protection) technology was developed to allow organic acids to reach the distal parts of the GIT without being totally dissociated, being released progressively, thus maintaining their efficacy and allowing the use of a reduced inclusion rate. One has to remember that the bulk of the GIT bacteria population in pigs is found in the cecum and colon and the objective is to modulate this bacteria population and keep under control some pathogenic ones. This is particularly important with piglets at weaning time, undergoing numerous stresses, environmental changes, solid feeds, disease challenges, mingling with other piglets, etc.

There are numerous microencapsulation technologies but not all of them are suitable for animal nutrition, when purchasing a microencapsulated blend of organic acids, one should always ask for a clear demonstration of real protection and “in vivo” slow release in the intestine.

The microencapsulation of organic acids, on top of being more efficacious in the GIT, has many technological advantages. It will control dustiness, corrosiveness and aggressive odour of organic acids as well as protecting the workers manipulating them and the environmental impact in the feed mill and around it.

Bacteria exposed to certain organic acids in an acidic environment (like the stomach of a piglet), but not enough to kill them, might develop a type of “acid tolerance”. When re-exposed to the same acids later on, they can be more tolerant to it. The microencapsulation of organic acids will avoid this exposure to low pH because it bypasses the stomach and will liberate only when reaching the intestine, under the activity of bile acids and lipase.

Piglets at weaning are limited in their stomach hydrochloric acid production capacity and an acidic shock produced by free acids (non microencapsulated) will depress further that capacity (via a retro feedback mechanism), again this is avoided when using microencapsulated organic acids.

Table 1: Experimentally determined values of MICs of undissociated and dissociated organic acids (various authors)

Figure 1: Ideal release pattern of microencapsulated organic acids in the pig digestive tract.

Advantages of microencapsulated organic acids over free organic acids in pig nutrition:

• No stimulation of salivary secretion (reducing the buffering effect of saliva)

• No damage to the stomach mucosa

• No reduction of the physiological production of HCl in the stomach

• No negative effect on feed intake

• No triggering effect on bacteria tolerance to organic acids (acid stress)

• Extending the antibacterial effect of organic acids all along the intestinal tract

• No risk of inducing bone calcium deposition reduction

• Using lower inclusion rate in the feed

The most recent development in the use of organic acids in pig is taking advantage of the strong synergy between microencapsulated organic acids and essential oils. The protection of essential oils is absolutely necessary to avoid its dispersion during feed manufacturing and to avoid its rapid absorption at the stomach and proximal duodenum level in piglets.