Xylanase in Corn-Based Pig Finisher Diets

With feed making up 70% of the production costs in swine, technologies that can effectively improve feed efficiency are still a focus for producers targeting a lower overall cost of production, writes Dr Pete Wilcock, AB Vista Global Technical Manager.Fibre-degrading enzymes have been extensively used in broilers in both non-viscous and viscous diets, and are becoming more of a focus for pig producers in corn based rations. It is understood that fibre-degrading enzymes increase nutrient digestion and consequently animal performance.

The application of fibre-degrading enzymes – of which xylanases are the most commonly used and efficacious – has also tended to focus primarily on pig diets containing viscous grains, such as wheat and barley. This in part may be attributed to the understanding that the addition of xylanases reduces the impact of viscosity in the pig gut and that increased viscosity is more typical with barley and wheat, but not corn.

However, new research has shown a six point improvement in FCRc (weight corrected) in finisher pigs fed corn-based diets supplemented with a single xylanase, Econase XT. This is particularly good news for finisher pigs fed cheaper, less digestible diets and also for the producers feeding them.

Consistent trial results

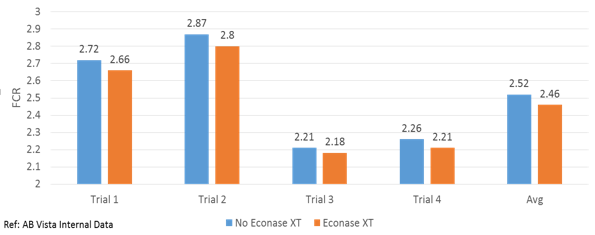

The results of four recent pig trials evaluating the addition of Econase XT xylanase to corn-soya or corn/soya/distiller grain based diets, showed that the enzyme improved FCRc by six points when compared to the control (2.46 vs 2.52, see Figure 1).

Figure 1 – The effect of Econase XT xylanase on FCRc in pig finishers (Source: AB Vista, 2015)

The above trials clearly demonstrate that a consistent response from xylanase application in non-viscous diets is achievable. This success was achieved with pigs starting on the enzyme in the early nursery period and being fed on the enzyme program all the way to slaughter. This maximised the production of the animal across the whole growth period, leading to greater improvement and consistency in response.

Xylanase mechanism and effect explained

The mechanisms go a long way to explaining the nutrient utilisation improvements seen in corn-soya-based diets when xylanases are applied effectively.

The reason xylanases such as Econase XT are so effective across the full spectrum of cereal types is that arabinoxylans typically represent approximately 40-50% of the total fibre polysaccharides found in finisher diets, whether based on wheat, barley, corn or sorghum. Furthermore, it is now recognised that the benefits that come from the breakdown of arabinoxylans by an effective xylanase feed enzyme may well go beyond reducing the negative effects of increased gut content viscosity.

In addition, xylanases can deliver improved nutrient digestibility in non-viscous diets through a mechanism which involves the breakdown of long-chain arabinoxylans into small-chain xylo-oligomers. This opens up the cell walls in the feed, releasing nutrients for digestion by the animal’s own enzymes. These xylo-oligomers may also act as prebiotics, encouraging the growth of a well-balanced and positive intestinal microbiota.

As such, reliable and consistent performance response to xylanase use in corn-based diets is likely to rely heavily on achieving the right levels of enzyme activity across the animal gut. The specific characteristics of the xylanase which determine the type and extent of arabinoxylan breakdown are therefore critical if the expected response is to be seen within the animal.

Positive effect in grower finishers

The impact of this mechanism appears to be particularly pronounced in finishers. As a pig ages, it has the ability to utilize a greater portion of the volatile fatty acids (VFA) produced from oligosaccharides by the gut microflora, with up to 30% of the energy from degraded fibre utilized by the animal.

By improving the supply of short-chain xylo-oligomers and promoting beneficial microbiota fermentation, the application of an effective xylanase to corn- or sorghum-based diets may also therefore increase VFA production. The net result could be an improvement in energy supply, growth and FCR. In grower finisher pigs when feed intake is high, such improvements all the way up to slaughter offer real value to the producer.

Critical xylanase thermostability

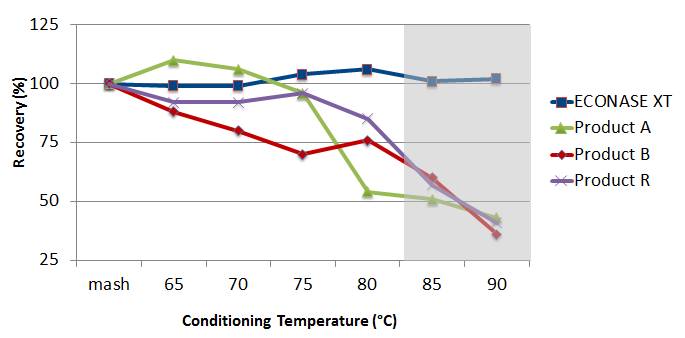

However, in order for such performance benefits to occur, it is important that the xylanase can both survive the proteolytic conditions of the stomach – to remain active – and is sufficiently thermostable to withstand any pelleting or other high temperature feed processing. Any reduction in the level of enzyme activity at the point of action within the pig’s upper gastrointestinal tract will clearly negatively affect the ability to break down dietary arabinoxylans.

Figure 2 shows Econase XT to be thermostable at up to 90°C (194°F) under normal pelleting conditions, which in this case included 30 seconds of steam conditioning followed by pelleting through a 3.0 mm die.

Figure 2 – Thermostability of Econase XT in comparison to competitor xylanases claiming high intrinsic thermostability (Source: Kolding Technology Institute, 2006-7)

Confirming active dose

Such detail is critically important when looking to maximise response from fibre-degrading enzyme use. This includes ensuring that there is an effective methodology available for confirming that expected levels of active enzyme are indeed being delivered to the pig.

If the performance response isn’t as expected, any assumptions made without first determining whether the applied enzyme dose is reaching the upper gastrointestinal tract could easily lead to the wrong steps being taken to correct the problem. For example, Econase XT xylanase can be quickly and easily confirmed on farm or analysed at the point of feed manufacture, without the need for lengthy laboratory procedures using unique ELISA technology.

Thus, as part of an overall strategy to ensure the greatest levels of reliability and consistency in response from xylanase use, thermostability and assayability are important factors. Combined with a greater understanding of the mechanisms involved in generating that response, the result should be both greater levels of confidence in the use of xylanases feed enzymes in finisher diets, and greater returns for those pig producers willing to make the most of the opportunity to use them.