What are the impacts of stress on pork quality?

When aiming for optimal pork quality, a stressful environment is your worst enemy.It is well known that stress has a negative impact on meat quality. No matter how good your pig is when it’s loaded onto the truck, it’s carcase value will decrease if it has been stressed in the 15 minutes prior to slaughter. Taking the time to manage stressors during transport, lairage and stunning will improve carcase quality and benefit your bottom line.

When pigs are stressed prior to slaughter it can impact carcase quality in two ways:

The first is by increasing the amount of fighting that occurs within the group, resulting in higher rates of bruises and carcase lesions.

The second is by altering the chemical properties of the meat, resulting in poorer eating quality and less functional uses for the meat. These changes can result in pale, soft, exudative (PSE) or dark, firm, dry (DFD) meat, depending on the stressors experienced.

Pale, soft, exudative (PSE) meat is characterised by its pale colour and its poor water holding capacity. This means that it has a high drip loss, becomes tough and flavourless after cooking, and is not well suited for processing into products such as ham.

Dark, firm, dry (DFD) meat is characterised by its darker colour, spoils more rapidly, is less appealing to consumers.

Both PSE and DFD are caused by an inappropriate pH value in the muscles of the pig after slaughter. pH is a measure of how acidic something is, and PSE meat is too acidic (it has a low pH value), while DFD meat is not acidic enough (it has a high pH value). Ideally, the muscle pH will be within the range of 5.6-5.7 within 3-5 hrs of slaughter to avoid PSE or DFD. To understand how stress can alter the pH value of pork, it will help to briefly describe the stress response.

The stress response

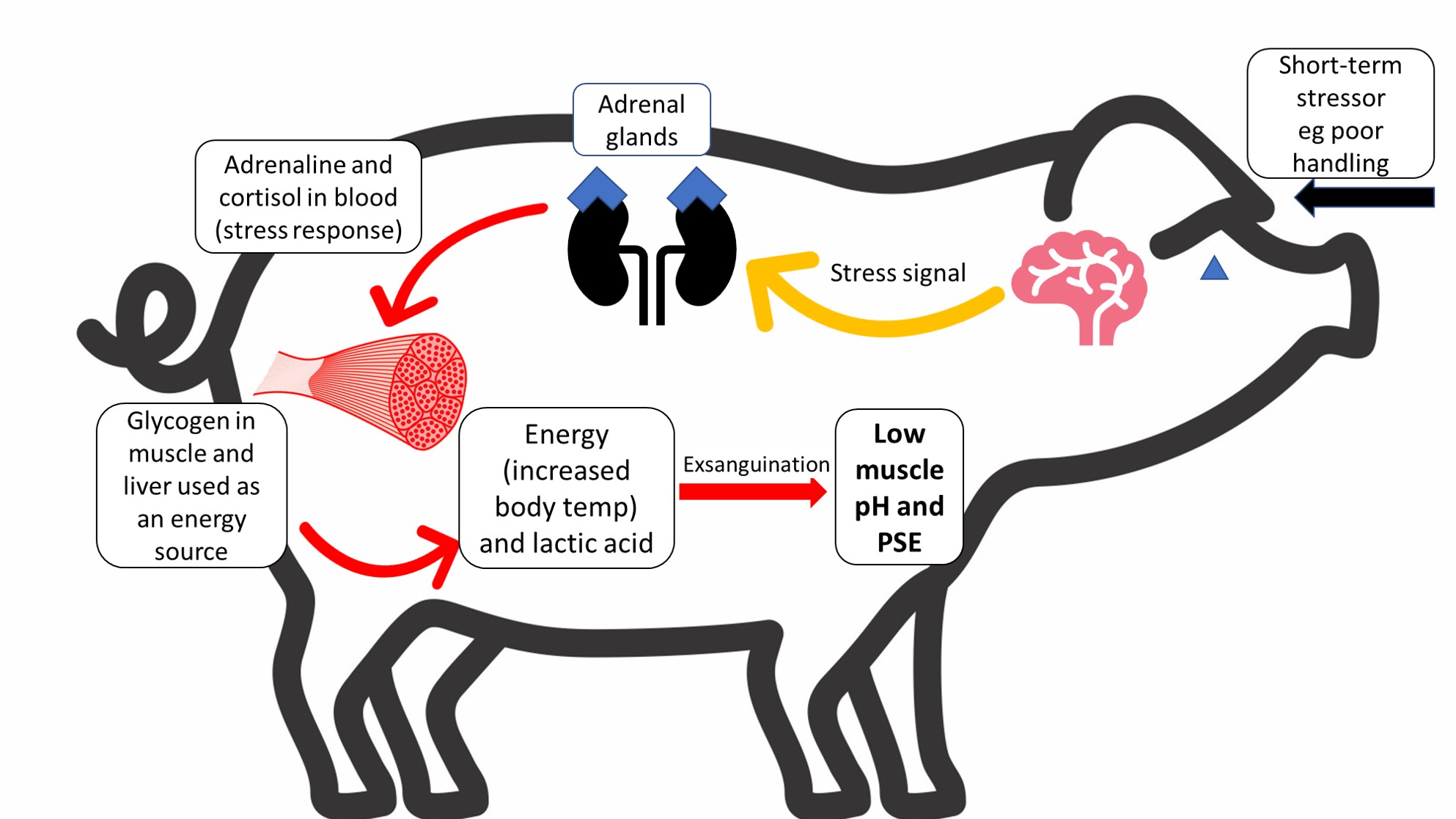

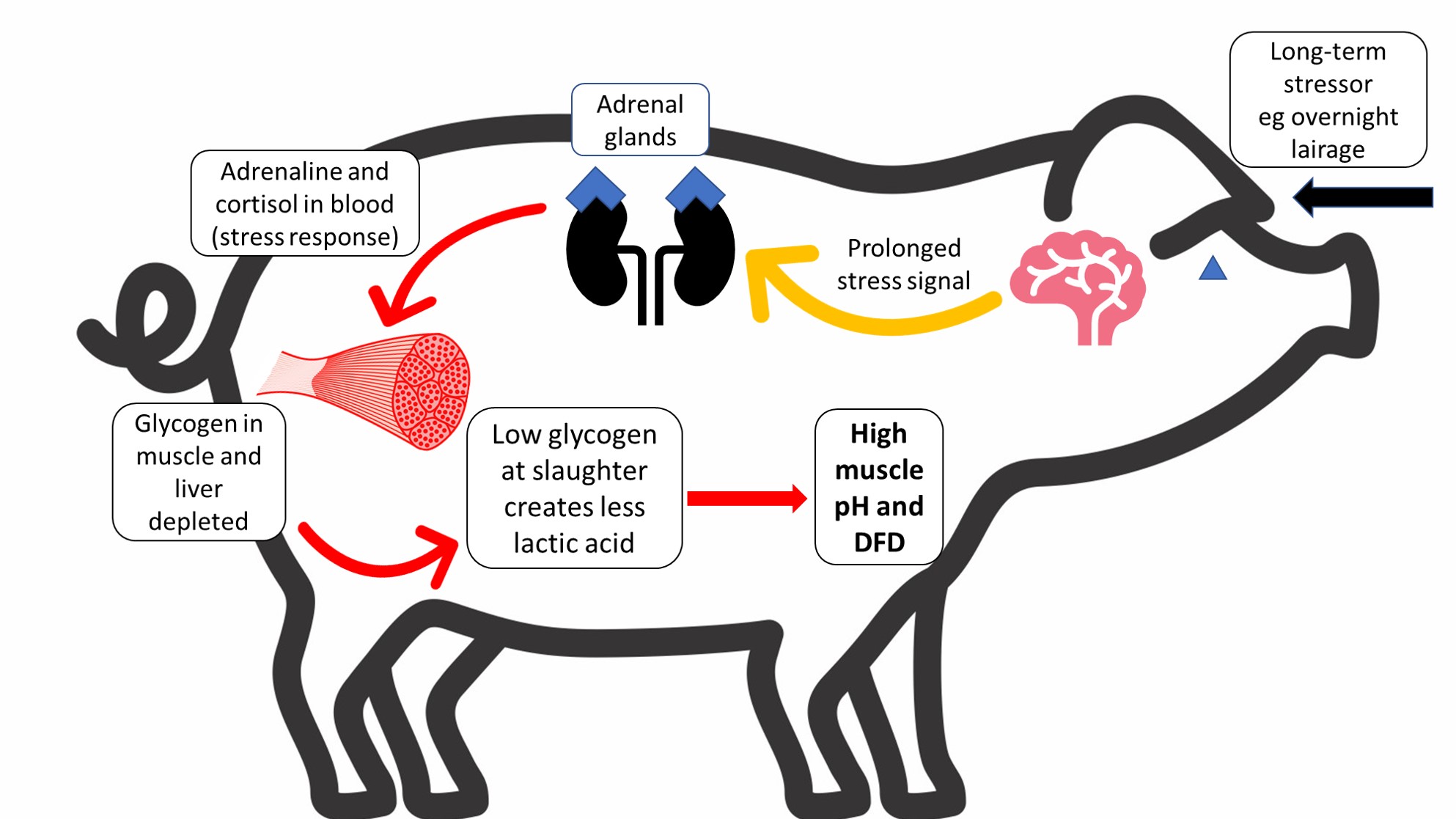

When an animal perceives a threat, stress hormones (cortisol and adrenaline) are released into the bloodstream which mobilises energy for use in the ‘fight or flight’ response. This energy is sourced from a substance called glycogen, which is stored in the muscles and liver, and provides a rapidly available source of energy for use in emergencies. To access this energy, the glycogen is converted to glucose, and then into lactic acid. The lactic acid is the primary factor dictating the pH of muscle tissue.

When pigs are exposed to a severe short-term stressor, their metabolism and body temperature increases. If this occurs just prior to slaughter, the pigs will be exsanguinated while their metabolism and body temperature are still high. This means that there is no blood left in the carcase to remove the lactic acid build up that is occurring as the cells continue to metabolise glycogen, hence the pH decreases. The high temperature and the low pH damage the muscle proteins and they lose their water holding capacity, resulting in PSE meat.

In comparison, when pigs experience a long-term stressor, such as overnight stays in lairage that result in a lot of fighting, the pigs use up their glycogen reserves and have very little left at the time of slaughter. This means that there is less glycogen available in the muscles to be converted into lactic acid post-mortem. The less lactic acid present in the muscle tissue, the higher the pH value of the meat, resulting in DFD meat.

In an ideal scenario

Ideally, the aim is to have your pigs being slaughtered with as much glycogen in their muscles as possible, combined with minimal stress in the period immediately prior to slaughter. This will help to ensure that muscle pH is kept within the optimum range for good meat quality. To achieve these conditions, pigs need to be rested after transport, and managed in a low-stress manner. Listed below are some of the common stressors that pigs experience during transport and lairage, and how to reduce their impact.

Handling

Good facility design and automated handling equipment in abattoirs can reduce pre-slaughter stress, as does low-stress handling techniques without the use of an electric prod or excessive force to move pigs. Walking the pens on farm will help the pigs get used to human contact.

Novelty

Providing enrichment on farm will help the pigs get used to change so that they find it less stressful. A larger space allowance on farm can increase physical fitness, which will reduce fatigue.

Social mixing

Use smaller group sizes where possible and limit the time in lairage to 2-4 hours maximum. This allows the pigs to recover from transport without exposing them to prolonged social mixing.

Heat stress

Pigs cannot sweat and are very susceptible to heat stress. Ensure there is adequate ventilation provided on the truck and in lairage. Showering the pigs with cool water when temperatures are above 21°C will reduce overheating. Pigs should be slaughtered immediately during hot weather, as lairage will exacerbate heat stress.

Cold stress

Providing adequate bedding in the truck during very cold weather will shield the pigs from the cold metal floor, allowing them to lie down and conserve energy.

Feed deprivation

Fasting the pigs for 16-24 hrs is considered an adequate compromise between pig welfare and food hygiene requirements. Prolonged fasting is associated with increased skin lesions from fighting and DFD.

Mindful management

While it is easy to focus on measures such as muscle temperature and pH when discussing the impact of stress on meat quality, we need to remember that these measures translate to subjective experiences for the pigs being slaughtered. For example, low muscle glycogen is associated with fatigue, and long fasting periods are associated with hunger. Being aware that the way pigs behave during the pre-slaughter period is a generally a response to hunger, fear, fatigue and novelty can help us to remain calm and handle these animals with patience and compassion, with benefits for meat quality.

In conclusion, there is a complex interplay between farm, transport, lairage and handling variables that influence meat quality through their effects on stress and fatigue for pigs. Preparation can begin on farm to produce best quality pork, and transport and lairage stressors can be minimised, however despite these precautions, the handling that the pigs receive in the 15 mins prior to stunning can still reduce the quality of the product. Mistakes made at this point in the production chain, such as stressful handling techniques and electric prod use, cannot be corrected. It is therefore vital that in addition to best practice production, transport and lairage, the handling and facilities at abattoirs are maintained at optimal performance.

| References | ||||

|---|---|---|---|---|

| Faucitano, L.. | ||||

| (2018) | Preslaughter handling practices and their effects on animal welfareand pork quality.. Journal of Animal Science | 96: 728-738 | ||

| Miller, R. K. | ||||

| (2002) | Chapter 3: Factors affecting the quality of raw meat.. Meat Quality | 27-63 | ||

| Wariss, P. D. | ||||

| (2003) | Optimal lairage times and conditions for slaughter pigs: A review.. Veterinary Record | 153: 170-176 |