Welfare of Pigs During Transport

To maintain an adequate level of animal welfare during the marketing process requires having a fit pig that is carefully managed and handled, according to Dr Temple Grandin of Colorado State University. She explains how to achieve this in a factsheet for Pork Information Gateway.Introduction

Good handling and transportation practices will improve pig welfare and reduce transport losses. This factsheet will provide guidance on handling during loading on the farm, truck stocking density, and fitness of pigs for transport. It will also include recommendations on transport practices during hot summer weather and cold winter weather to help prevent losses.

Objective

The purpose of this paper is to review scientific information on pig welfare during transport and to provide practical information.

Loading and Unloading Equipment

Non-slip flooring is essential on loading ramps and alley floors. A good non-slip finish can be achieved by impressing wet concrete with a stamp made from expanded metal mesh.

The ramp angle should never exceed 20 degrees for a non-adjustable ramp and 25 degrees for an adjustable ramp [1]. Market pigs have become much heavier and recently in 2014 the recommended ramp angle decreased to less than 20 degrees [2,3]. Fifteen degrees or less is recommended for heavy 275 lb. (125 kg) pigs, for both adjustable and non-adjustable ramps. A pig’s heart rate will increase as the angle of a loading ramp increases [4,5]. Cleats on ramps should be spaced to fit the normal walking stride of an animal [4]. For 250-lb. (114-kg) market weight pigs, the cleats should be on 8-inch (20-cm) centres, using 1 inch × 1 inch (2.5 × 2.5cm) cleats. Missing cleats must be immediately replaced to prevent leg injuries. Stairsteps work well on concrete ramps [2]. For market weight pigs, they should have a 2.5-inch (6-cm) rise and a 10-inch (25-cm) long tread [1].

The author has observed that small piglets can get dewclaw injuries when they go down a ramp designed for market-weight pigs. The piglets slip and damage their dewclaws because the cleats are too far apart. To prevent injuries to young piglets, small closely spaced cleats are required. In segregated early weaning facilities ramps with small closely spaced cleats must be provided unless the loading and unloading docks are level with the truck.

Further information on the design of loading ramps can be found in Grandin [1,6]. Good maintenance of equipment is essential to prevent accidents that can injure either pigs or people.

Pig movement through alleys and chutes can be greatly affected by air movement, shadows, and lighting. Pigs have a tendency to move from a darker area towards a brighter area but they will not approach blinding light [5,7]. Adding a lamp or moving a lamp will often facilitate animal movement [8].

Pigs will balk at air blowing in their faces. Pig movement out of the finishing barn can often be improved by opening the curtains to let in daylight and to equalise the air pressure. At night, lights are effective for attracting pigs into trucks or trailers. Pigs will often move up a ramp more easily if they are moved outside of the building on level ground before they encounter the ramp.

Handling Methods

Quiet handling by well-trained people is essential. Handlers should be trained to use behavioral principles of handling such as the flight zone and point of balance [1]. Flags, plastic paddles or panels should be used as the primary driving aids. For moving pigs through narrow alleys, less time is required when a pig board is used [9].

Frequent use of electric prods is detrimental to pig welfare because shocking increases body temperature, lactate levels, heart rate, and the incidence of stressor non-ambulatory pigs [10,11,12]. Electric prods must not be used as the primary driving aid.

When pigs are loaded out of either a segregated weaning facility or a finishing barn, it is best to move small groups directly from the home pens to the truck. For finishing pigs, it is recommended to move three to five pigs at a time for loading trucks [13,14]. One study showed that moving four pigs at a time was best [2]. Good handling requires more walking to move small groups, because the handler has to make more trips to walk back and forth between the pens and the loading ramp. For smaller pigs, larger numbers may be moved at a time. Pigs should be moved without piling up.

Handling of market weight pigs will be easier if the alley in a finishing building is 36 inches (90cm) wide. This allows two market weight pigs to walk down the alley side-by-side.

It is the author’s professional opinion that both genetics and previous experience will affect the ease of handling of pigs. Piglets that have never walked on concrete may balk and be difficult to move. Moving the animals will be easier if they are given an opportunity to explore the new floor surface prior to being moved over it.

Pigs from certain lean genetic lines may be more excitable and difficult to drive [15]. High lean pigs are more fearful and explore an open arena less [16]. More recent research shows that restless behaviour in pigs is heritable [17]. Selection for leanness tends to increase excitability and, in contrast, selection for growth rate may lead to less excitability [18]. When selection for both leanness and growth rate, high lean pigs had significantly more fights [19].

Work by the author with producers has shown that excitability can be reduced and the pigs will be easier to drive if the producers walk through the pens every day [1]. Walking in the pens or allowing pigs to walk in the aisles can produce calmer, less excitable animals [20]. Producers should walk through pens to teach the pigs to quietly get up and flow around them. Pigs can differentiate between a person in the aisle and a person in their pens. British researchers have reported that pigs from certain farms are more difficult to drive [21].

Pigs with previous experiences with handling are easy to move. Pigs which have been moved out of their pens and into the aisles during finishing are easy to drive [21, 22]. Moving the pigs out of the finishing pens a month prior to slaughter also improve their willingness to move [23]. Pigs that have experience moving through alleys and ramps require less time to handle them in the future [24]. Sorting pigs 18 hours before loading can reduce loading time [25].

Conditions on the Truck

Overloading of trucks may be a major cause of increased stress and death loss [26,27]. Severe overloading of trucks results in clear evidence of physical stress [28]. On long trips, pigs should have sufficient room to lie down without having to be on top of each other [29]. For market weight pigs weighing 288 lb. (131 kg), losses are reduced when each pig has a minimum of 0.462 square metres, 4.97 square feet) of floor space on the truck [26,30].

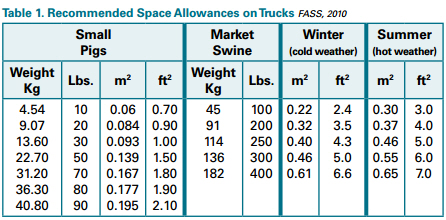

Market weight pigs remain standing when a trip is under 3 hours and they lie down for longer trips [31]. On longer trips, more space will be required so that all of the pigs will have space to lie down without being on top of others [32]. During hot weather when the Livestock Weather Safety Index is in the Danger or Emergency Zone, load 15 to 20 per cent fewer pigs. Table 1 [32] shows recommended space allowances for trips under three hours. For longer trips, increase the space 15 to 20 per cent depending on air temperature.

Research has shown that pigs can suffer from motion sickness [33]. This is probably due to low frequency vibration [34]. Feed withdrawal prior to transport will help prevent motion sickness and vomiting during transport. Feed withdrawal 16 to 24 hours prior to stunning will also help prevent carcass contamination and may help reduce pale soft exudative (PSE) meat [35,36]. Longer fasts would be detrimental to animal welfare and reduce carcass weight. Pigs must be provided with water until loading and immediately after unloading.

To keep pigs warm in the winter and to prevent frostbite, deep bedding with either straw or shavings is required when the temperature is below 32°F (0°C). When the temperature drops to 10°F (-12°C), straw is recommended for extra warmth. On aluminium-sided trailers, plastic boards can be inserted to block ventilation holes.

When the temperature is below 20°F (-6°C) the trailer should be 96 per cent boarded [3]. When the temperature rises to 60°F (16°C) all the boards should be removed [3]. For intermediate temperatures, the trailer can be 25 per cent to 50 per cent boarded. During extreme cold, the trailer may have to be lined with wood or plastic to prevent the pigs from contacting cold metal.

During the summer when the temperature is over 60°F (16°C), wet shavings or sand should be used. Straw bedding is too hot and excessive bedding may increase deaths [3]. At 80°F (27°C), pigs should be sprinkled with water immediately after loading. After sprinkling, the truck should immediately start moving to create evaporative cooling. Wetting pigs in a stationary truck can cause problems with high humidity and a “sauna” effect.

Heat builds up rapidly in a stationary vehicle. If a truck has to stand when the temperature is over 80°F (27°C), it should be parked by a fan bank. Another good alternative when a packing plant has a break-down is to provide ventilation by keeping the trucks moving. Death loss increases as temperatures increase (37,38). Truck drivers should drive carefully and avoid sudden stops and rapid acceleration.

Fitness of the Pigs for Transport

One of the most important factors which will determine if a pig is fit for transport is its condition before it is loaded onto the truck. Sows should be marketed when they are fit for travel. The National Pork Board advises that sows and pigs that are unable to walk or those that are ill and will not recover should be humanely euthanised on the farm. They should not be transported through market channels. Pigs which have temporarily become non-ambulatory must be allowed to recover before they are put on a truck.

Another factor that can affect pig handling and transport is feeding ractopamine (Paylean). High doses of ractopamine can make pigs more sluggish and slower to move [39]. Pigs fed 20mg per kg of ractopomine are more susceptible to handling stress when they are handled aggressively and shocked with electric prods [40]. Finishing pigs fed a low dose of 10mg per kg had no effect on the percentage of non-ambulatory pigs [41]. The author has observed at slaughter plants that there have been increased problems with non-ambulatory pigs due to excessive dosages of re-partitioning agents. These drugs must be used carefully.

Producers need to select sound animals with good feet and legs. Genome studies may help producers select for structural soundness [42]. In 2014 the author observed continuing problems with lame market pigs due to poor leg conformation. The most common types of poor conformation are straight “post legs” or animals with collapsed ankles where their dewclaws touch the floor. Lame animals are more likely to go down and become non-ambulatory during transport.

The presence of the stress gene will increase death loss during transport. A Canadian study found that 9.2 per cent of the pigs that were homozygous positive for the stress gene died during transport [43]. Death loss percentages were 0.27 per cent in heterozygous stress gene carriers and 0.05 per cent in pigs that were stress gene free. Fortunately many producers are now selecting pigs that are stress gene free to improve meat quality. A survey of pigs dead on arrival at the slaughter plant indicated that deaths decreased from 0.27 per cent to 0.1 per cent when the stress gene was removed [44]. USDA data shows that the percentage of dead pigs arriving at packing plants decreased from 0.3 per cent in 1998 to 0.15 per cent in 2011 [45]. In the United States, the frequency of HAL porcine stress is low. Only 2.3 per cent of US pigs were carriers and 0.45 per cent were homozygous positive [46].

Fatigued Pigs

Fatigued pigs are market weight animals that become fatigue and lay down and refuse to walk. They are not injured and if they are allowed to rest, they often recover. A number of different factors contribute to the incidence of fatigued pigs. Death loss increases during hot weather but fatigued pigs usually increase when weather gets cold [3].

There are several different factors that may increase the percentages of fatigued pigs, including growing pigs to very heavy market weights, long transports, poor leg conformation and high doses of ractopomine. It is a multifactorial problem.

The author observed at one plant that fatigued pigs were reduced by making three changes. They were switching to a lower dose of ractopomine, improving leg conformation by changing breeding, and initiating a programme to encourage producers to walk the finishing pens. Walking the pens gets pigs accustomed to people walking through them, which facilitates truck loading. After the changes were made, the plant was able to have a single employee handling non-ambulatory pigs. Before the changes, four or five full-time employees were required to handle non-ambulatory pigs.

Incentives to Reduce Losses

People manage the things that they measure. Handling and stunning practices at packing plants improved when procedures were monitored and measured [47, 48]. At one plant, death loss was greatly reduced when truck drivers received rewards for low death loss. Financial incentives can be very effective at preventing losses of pigs during transport and handling.

Holding people accountable for losses is another motivator to help prevent losses. Bruises in cattle greatly reduced when people were held financially accountable for them [49].

Conclusions

To maintain an adequate level of animal welfare during the marketing process requires having a fit pig that is carefully managed and handled. Managers need to be committed to training and supervising employees to ensure high standards of animal treatments.

Literature Cited

- Grandin, T. Animal handling, In: E.O. Price (Editor) Farm Animal Behavior. Vet. Clin. N. Amer., Food Anim. Prac., 1987; 3(2):323-338.

- Berry, N.L., Johnson, A.K., Hill, J., Longeragan, S., Karriker, L.A. and Stalder, K.J. Loading gantry versus traditional chute for the finisher pig: Effect on welfare at the time loading and performance measures and transport losses at the harvest facility, J. Anim. Sci., 2012; 90:4028-4036.

- McGlone, J.J., Johnson, A.K., Sapkota, A., and Kephart, R.K. Transport of market pigs: Improvements in welfare and economics, In: T. Grandin (Ed) Livestock Handling and Transport, CAB International, Wallingford, Oxon, UK. 2014; Pp. 298-314

- Mayes, H.F. Design criteria for livestock loading chutes, American Society of Agricultural Engineers Paper, 1978; 78:6014, St. Joseph, MO.

- van Putten, G. and Elshof, W.J. Observations of the effects of transport on the well being and lean quality of slaughter pigs. Anim. Red. Stud., 1978; 1, 247-271.

- Grandin, T. Design of loading facilities and holding pens, Appl. Anim. Behav. Sci.,1990; 18, 187-201.

- Grandin, T. Pig behaviour studies applied to slaughter-plant design, Applied Anim. Ethol., 1982; 9:141-151.

- Grandin, T. Factors that impede animal movement at slaughter plants, J. Amer. Vet. Med. Assoc., 1996; 209:757-759.

- McGlone, J.J., McPherson, R.L., and Anderson, D.L. Case study: Moving devices for finishing pigs: Efficacy of electric prod, board, paddle or flag, Prof. Anim. Sci., 2004; 20(6):518-523.

- Brundige, L., Okeas, T., Doumit, M., and Zanella, A.J. Loading techniques and their effect on behavior and physiological responses of market pigs, J. Anim. Sci. 1998; 76 (1) 99 (Abstract).

- Benjamin, M.E., Gonyou, H.W., Ivers, D.L. Richardson, L.F. Jones, D.J., Wagner, J.R., Seneriz, R. and Anderson, D.F. Effect of handling method on the incidence of stress response in market swine in a model system. J. Anim. Sci., 2001; 79:279 (Supl. 1)(Abstract).

- Bertel, T.M., Ellis, M., Ritter, M.J., and McKeith, F.K. Effect of feed withdrawal and handling intensity on longissimus muscle glycolytic potential and blood measurements in slaughter weight pigs, J. Anim. Sci., 2005; 83:1536-1542.

- National Pork Board, Transport Quality Assurance (TQA) Handbook, Des Moines, Iowa, 2008

- Lewis, C.R.G. and McGlone, J.J. Moving finishing pigs in different group sizes, cardiovascular responses, time and ease of handling, Livestock Sci., 2007; 107:85-90.

- Grandin, T. Assessment of stress during handling and transport, J. Anim. Sci., 1997; 75:249-257.

- Shea-Moore, M. The effect of genotype on behavior in segregated early weaned pigs in an open field. J. Anim. Sc. 1998; 76:1 (Supl. 1). 100 (Abstract).

- Holl, J.W., Rohner, G.A., and Brown-Brandl, T.M. Estimates of genetic parameters among scale activity scores, growth, and fatness in pigs, J. Anim. Sci, 2010; 88:455-459.

- Rydhmer, L., and Canario, L. Behavioral genetics in relation to pig welfare, In: T. Grandin and M.J. Deesing (Editors) Genetics and the Behavior of Domestic Animals, Academic Press (Elsevier) San Diego, CA, 2014; pp. 397-434.

- Buss, C.S. and Shea-Moore, M.M. Behavioral and physiological responses to transportation stress. J. Anim. Sci., 1999; 77 (1), 147 (Abstract).

- Grandin, T., I.A. Taylor and S.E. Curtis. Richness of pig’s environment affects handling in chute. J. Anim. Sci., 1986; 63(1)161 (Abstract).

- Hunter, E.J., Weeding, C.M., Guise, H.J., Abbott, T.A. and Penny, R.H. Pig welfare and carcass quality: a comparison of the influence of slaughter handling systems in two abattoirs. Vet. Rec., 1994; 135, 423-425.

- Geverink, N.A., Kappers, A., van de Burgwal, E., Lambooij, E., Blokhuis, J.H., and Wiegant, V.M. Effects of regular moving and handling on the behavioral and physiological responses of pigs to pre-slaughter treatment and consequences for meat quality, J. Anim. Sci., 1998; 76:2080-2085.

- Abbott, T.A., Hunter, E.J., Guise, J.H. and Penny R.H.C. The effect of experience of handling on pig’s willingness to move, Appl. Anim. Behav. Sci. 1997; 54:371-375.

- Lewis, C.R.G., Hulbert, L.E., and McGlone, J.J. Novelty causes elevated heartrate and immune changes in pigs exposed to handling alleys and ramps, Livestock Sci., 2008; 116:336-341.

- Gesing, L.M., Johnson, A.C., Selsby, J.T., Freurbach, C., Hill H., Faga, M., Whiley, A., Bailey, R.T., Stalder, K.J., and Ritter, M.J. Effects of presorting on stress responses at loading and unloading and impact on transport losses from market weight pigs, The Prof. Anim. Sci., 2010; 26:603-610.

- Ritter, M.J., Ellis, M., Brinkman, J., DeDecker J.M., Keffaber, K.K., Kocher, M.E., Peterson, B.A., Schlipf, J.M. and Wolter, B.F. Effect of floor space during transport of market weight pigs on the incidence of transport losses at the packing plant and relationships between transport conditions and losses, J. Anim. Sci., 2006; 84:2856-2864.

- Pilcher, C.M., Ellis, M., Rojo-Gomez, A., Curtiss, S.E., Wolter, B.F., Peterson, C.M., Peterson, B.A., Ritter, M.J., and Brinkman, J. Effects of floor space during transport and journey time on indicators of stress and transport losses in market weight pigs, J. Anim. Sci., 2011; 89:3809-3818.

- Warriss, P.D. Choosing appropriate space allowances for slaughter pigs transported by road: A review, Vet. Rec., 1998; 142:449-454.

- Lambooij, B.E. Transport of Pigs, In: T. Grandin (ed) Livestock Handling and Transport, CAB International, Wallingford, Oxon, UK, 2014; pp. 280-297.

- Ritter, M.J., Ellis, M., Bertelsen, C.R., Bowman, R., Brinkman, J., DeDecker, J.M., Keffabert, K.K., Murphy, C.M., Peterson, R.A., Schlipf J.M., and Walter, B.F. Effects of distance moved during loading and floor space on the trailer during transport on losses of market weight pigs on arrival at the packing plant, J. Anim. Sci., 2007; 85:3454-3461.

- Guise, H.J., Riches, H.L., Hunter, B.J., Jones, T.A., Warriss, P.D., and Kettlewell, P.J. The effect of stocking density on transit on carcass quality and welfare of slaughter pigs, Meat Sci., 1998; 50:439-446.

- FASS. Guide for the Care and Use of Agricultural Animals in Research and Teaching, 3rd Edition, Federation of Animal Science Societies, Champaign IL. 2010, This chart is the same as the National Pork Board.

- Bradshaw, R.H., Parrott, R.F., Forsling, M.L., Goode, J.A., Lloyd, D.M., Rodway, R.G. and Broom, D.M. Stress and travel sickness in pigs: effects of road transport on plasma concentrations of cortisol, beta-endorphin and lysine vasopressin. Anim. Sci., 63, 1996;507-516.

- Randall, J.M. Human subjective response to lorry vibration: Implications for farm animal transport. J. Agric. Eng. Res., 1992; 52:295-307.

- Eikenbloom, G., Bolick, A.H., and W. Sybesman, Effects of feed withdrawal before delivery on pork quality and carcass yield, Meat Sci., 1990; 29:25-30.

- Warriss, P.D. Ante mortem factors which influence carcass shrinkage and meat quality, Proc. 39th Int. Congress of Meat Sci. and Technology, Calgary, Canada, pp. 51-56., 1993.

- Grandin, T. Livestock Trucking Guide, National Institute for Animal Agriculture, Bowling Green, Kentucky, 2002.

- Knowles, T., Warriss, P.D., and Vogel, K. Stress physiology during transport, In T. Grandin, Editor, Livestock Handling and Transport, CABI International, Wallingford, Oxfordshire, UK, 2007; p399-420.

- Marchant-Forde, J.N., Lay D.C., Pajor, J.A. Richert, B.T. and Schninckel, A.P. The effects of ractopamine on the behavior and physiology of finishing pigs, J. Anim. Sci., 2003; 81:416-422.

- James, B.W., Tokoch, W.D., Goodband, R.D., Nelssen, J.L., Dritz, S.S., Owen, K.D., Woodworth, J.C. and Sulabo, R.C. Effects of dietary L-Carnitine and ractopomine HCI on the metabolic response to handling in finishing pigs, J. Anim. Sci., 2013; 91:4426-4429.

- Puls, C.L., Ellis, M., Ritter, M.J., Trout, W.E., and Carr, S.N. Effects of ractopomine level on growth performance, carcass and meat quality and blood acid-base catecholamine responses to handling procedures in finishing pigs, Abstract 266, Midwest Am. Soc. An. Sci., 2014.

- Fan, B., Onteru, S.K., Du, Z.Q., Garrick, D.J., Stalder, K. and Rothschild, M.F. (2011). Genome wide association study identifies loci for body composition and structural soundness traits in pigs PLOS ONE, 2011; DOI:10 1371/journal.pone.0014726.

- Murray, A.C. and Johnson, C.P. Influence of the halothane gene on muscle quality and preslaughter death in western Canadian pigs. Can. J. of An. Sci., 1998; 78:543-548.

- Holtcamp, A. Gut Edema: Clinical signs, diagnosis and control. Proceedings of the American Association of Swine Practitioners, Proceeding, 2000; p337-339.

- USDA/FSIS, Reports on the rate of dead on arrival livestock at U.S. production facilities, U.S. Department of Agriculture, Food Safety Inspection Service, Washington, D.C., 2011.

- Ritter, M.J., Ellis, M., Hollis, G.R., McKeith, F.K., Orellena, D.G., van Genugten P., Curtis S.E. and Schlipf J.M. Frequency of HAL-1843 mutation of ryanodine receptor gene in dead and non-ambulatory-noninjured pigs on arrival at the packing plant, J. Anim. Sci., 2008; 86:511-514.

- Grandin, T. Objective scoring of animal handling and stunning practices in slaughter plants, Journal of the J. Amer. Vet. Med. Assoc., 1998; 212:36-39.

- Grandin, T. Effect of animal welfare audits of slaughter plants by a major fast food company on cattle handling and stunning practices, J. Amer. Vet. Med. Assoc., 2000; 216: 848-851.

- Grandin, T. Bruises on Southwestern Feedlot Cattle, J. Anim. Sci., 1981; 53(1):213 (Abstr).

Frequently Asked Questions

Q: What is the correct angle for a truck loading ramp?

A: A pig’s heart rate increases as the angle of the ramp increases. Market pigs have become much heavier and in 2014, the recommended maximum ramp angle has decreased from 20 degrees to 15 degrees.

Q: What is the correct cleat spacing for truck loading ramps?

A: For market pigs weighing 250lb (114kg), the cleats should be on 8-inch (20-cm) centres, using 1 inch × 1 inch (2.5cm × 2.5cm) cleats. For young pigs, small closely spaced cleats are required. Small pigs can get dew claw injuries when they go down a ramp designed for market-weight pigs.

Q: What are the best driving aids for moving pigs?

A: Flags, plastic paddles or panels should be used as the primary driving aids. For moving pigs through narrow alleys, less time is required when a pig board is used. Frequent use of electric prods is detrimental to pig welfare because shocking increases body temperatures, lactate levels, heart rate and the incidence of stressor non-ambulatory pigs. Electric prods must not be used as the primary driving aid.

Q: How many market weight pigs should be moved from a pen to the truck?

A: It is recommended to move three to five pigs at a time for loading trucks. One study showed that moving four pigs at a time was best.

Q: On aluminium-sided trailers, plastic boards can be inserted to block ventilation holes. What are the boarding requirements for different temperatures?

A: When the temperature is below 20°F (6°C) the trailer should be 96 per cent boarded. When the temperature rises to above 60°F (16°C), all the boards should be removed. For intermediate temperatures, the trailer can be 25 per cent to 50 per cent boarded.

Q: Does ractopomine (Paylean) have an effect on handling?

A: High doses of ractopomine can make pigs sluggish and slower to move. Pigs fed 20 m/kg of ractopomine are more susceptible to handling stress when they are handled aggressively and shocked with electric prods. Finishing pigs fed a low dose of 10mg per kg had no effect on the percentage of non-ambulatory pigs.

February 2015