Water Line Maintenance Important for Pig Production, Health

Providing a clean water source every day is essential to ensuring your herd’s health and best economic performance, writes Ontario Pork.The water lines that carry the water to your pigs are not transparent; it is not possible to see what is happening inside them. It is easy to forget about this part of the building when cleaning and disinfecting. Successful water sanitation begins with a thorough water line cleaning program. The variability and dynamics of water systems create cleaning challenges, but these can be overcome with water quality information, a little effort, the right tools, and some plumbing (Watkins, 2007).

Water sampling

To test for total coliform and E. coli in your water, you will need to get at least two sample bottles from your local health unit (Figure 1).

To test if there is contamination of the well, take a sample near the well head before any treatment system. Use the second bottle to test at the end of the furthest line in the barn to determine if there is any biological activity within your water line.

To take a water sample, remove all attachments from the faucet. Begin by disinfecting the faucet with a lighter. Keep the flame on the spout for 3-5 seconds to kill any bacteria on the outside of the faucet. For plastic faucets or an alternative to flame, swab the faucet with isopropyl alcohol at 70%.

Turn on the faucet and allow the water to flow for ten seconds before filling the bottle. While the

water is running, remove the sample bottle lid. To avoid cross contamination:

- Do not touch the inside of the lid or the mouth of the bottle

- Do not put the lid down

- Do not rinse out the bottle

- Do not touch the mouth of the bottle to the faucet while filling

Fill the bottle to the prescribed mark and close the lid firmly. Pack the bottles in an insulated cooler until they can be shipped to the local health unit. It is preferable to bring in samples immediately to the lab or within 24 hours after collection for accurate results. Similar protocols would be used for more comprehensive water tests.

When analyzing the results the total coliform and E. coli levels should be ideally zero. However, total coliform levels can be up to 10 units for safe drinking consumption. There is no acceptable level other than zero for E. coli.

Water Treatment System

Depending on your water quality, there are a variety of water treatment systems available. Some of these treatments include but are not limited to:

- Filtration for particulates or even finer particles including bacteria

- Water softening

- Iron/sulphur removal treatments

- UV treatment

- Chemical injection (chlorine, acid, ozone,hydrogen peroxide etc.)

- Reverse Osmosis

Your choice of treatment depends on initial water quality, capitol cost, maintenance costs, and on-going product costs. If an injector is used it is necessary to have separate units for medication and chemical injections.

Plumbing

If you are noticing decreased pressure on certain lines or drinkers you may have issues with particulates, scale, biofilm, or all of the above. Particulates can be addressed with high flow filtration, preferably down to 5 microns.

This may require staged filtration. Due to Ontario’s hard water it is recommended to use acid or “descaler” products as part of your waterline maintenance program. In extreme cases a water softener may be required. Biofilm is a result of iron reducing bacteria. This can be addressed with iron filters or products that can break up and prevent biofilm form forming such as acidifiers, chlorine or peroxide.

Left unchecked, water lines can become restricted and biofilm can harbour pathogens resulting in lower animal performance.

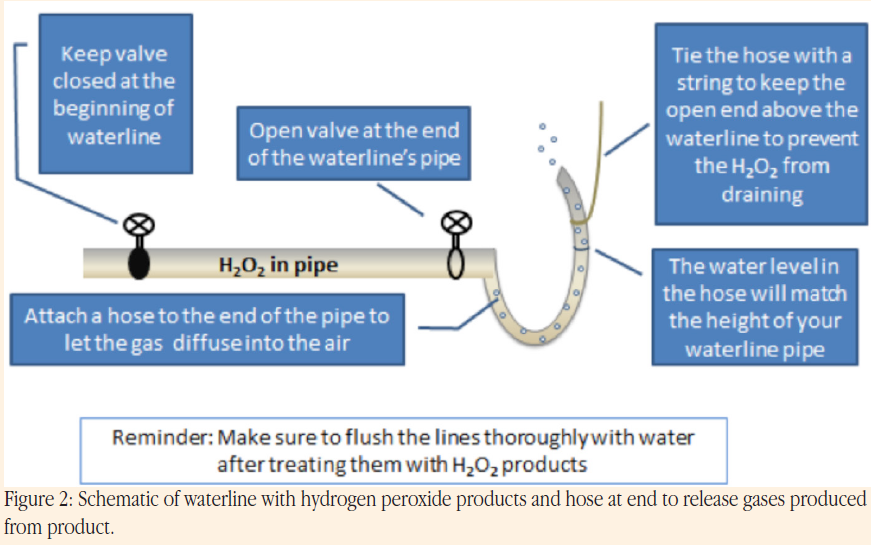

It is important to be able to isolate, treat, and flush your water system especially if you are in continuous production. An investment in manifolds, ball valves, and faucets can help accomplish this. You will need a bypass for chemical injectors and medicators, valves to isolate lines for treatment, and faucets at the end of lines to flush “descalers”, acidifiers, etc. If you are using a hydrogen peroxide treatment as a “descaler” (such as Proxi-Clean) you will need to add a length of hose at the end of a flush line to prevent the lines from bursting (Figure 2).

Water is considered the last nutritional frontier. Ontario has a lot of water but not all of it is suitable for livestock. If you would not drink the water why would you let your pigs drink it? Poor quality water has impacts on herd health, productivity, gestation, weaned pig average, weight gain, etc. You have high quality genetics, with high quality feed and high quality management; do not sabotage

your herd with low quality water or lack of water line maintenance.

With special thanks to Dr. Susan Watkins for the introduction and information used in this article based on her article, ‘Water Line Sanitation’.

Taken from Ontario Pork