Vegetable plasma: A new strategy to replace spray dried plasma in nursery diets

Hamlet Protein introduces Vegetable Plasma in the form of HP300Looking for a spray-dried plasma (SDP) replacement? Hamlet Protein introduces Vegetable Plasma in the form of HP300:

- HP300 contains almost no ANFs. Replacing SDP with HP 300 does not increase the level of antinutritional factors (ANFs) in the diet.

- HP300 is a fast digestible protein source like SDP. Replacing SDP with HP 300 ensures equally fast protein digestion.

- HP300 delivers high growth performance. Replacing SDP with HP 300 results in similar growth.

- HP300 is more economical than SDP. Replacing SDP with HP 300 reduces total feed costs.

Spray-dried plasma (SDP) is a premium protein ingredient used in nursery diets at a typical inclusion level of 3-5%. It is fed to nursery pigs to replace pharmacological levels of zinc or antibiotics or to improve growth performance in general. It is highly palatable and may aid in helping pigs respond to pathogenic challenges (Perez-Bosque et al., 2016). However, SDP is a costly ingredient and often associated with biosecurity issues. Spray-dried plasma has been associated with the spread of certain swine diseases, such as Porcine Epidemic Diarrhea virus (PEDv; Pasick et al., 2014). However, SDP is a costly ingredient.

Lowest level of anti-nutritional factors in the market

Anti-nutritional factors (ANFs) are known to cause many gastrointestinal (GI) disturbances in young animals. Spray-dried plasma contains no ANFs, so it does not cause gut health problems. Soybean meal (SBM), on the contrary, is very high in ANFs, so replacing SDP with SBM is not an option at all. The high amount of ANFs in SBM will reduce the protein digestibility, stimulate protein fermentation in the hindgut, change the osmotic balance in the intestines and directly damage the gut wall, causing inflammation.

An inflammatory response can be useful to cope with pathogens and eliminate them from the body. But, in the case of inflammation caused by ANFs, it results to be costly to performance as it leads in the partitioning of nutrients away from performance to support the immune system. Chronic inflammation therefore affects weight and body condition negatively. It has been estimated that protein synthesis in the muscle decreases by 23% under chronic intestinal inflammation while protein synthesis in the liver and the intestines increase by 63% and 19%, respectively (Mercier et al., 2002). Even subclinical (so not showing external signs) inflammation may significantly re-allocate nutrients to sustain the process and therefore reduce animal performance. Reducing inflammation in the gut through the reduction of ANFs in the diet is therefore a good strategy to maximize performance.

Soybean meal needs special treatment to remove the ANFs. Hamlet Protein uses a patented enzyme treatment to do so. During the production process all harmful ANFs, such as trypsin inhibitors, stachyose, raffinose and beta-conglycinin, are carefully reduced. This results in HP 300 – a specialty soy protein with the lowest level of ANFs in the market.

Speed matters when it comes to protein

The dynamics of protein digestion including the location and speed of the absorption of amino acids from the lumen of the small intestine are called protein kinetics. It considers the rate (speed) of the overall process, the site of nutrient digestion along the small intestine and the post-prandial bioavailability of amino acids. The protein kinetics are more indicative of feed efficiency and protein deposition than the extent of digestibility (SID values) per se.

Digestibility is usually used when protein ingredients are evaluated. However, the standard ileal digestibility coefficient (% SID) is rather limited as it does not say anything about absorption speed which affects post-absorption utilization of dietary amino acids.

The faster a protein is hydrolyzed the greater the possibility of the protein to be utilized for growth. Fast absorbable protein ingredients improve nitrogen (N) retention and feed efficiency of animals. The rate of protein hydrolysis, the consequent rate of amino acid (AA) absorption and the synchronization with AA from other protein sources are especially important in young animals, due to their high amino acid requirements for the synthesis of muscle tissue and vital organs. Faster protein hydrolysis soon after consumption (in proximal jejunum) leads to a faster absorption of amino acids after feeding. This increases the protein availability for tissues, milk, and organs, and ultimately results in increased protein deposition, lower FCR, reduced nitrogen excretion into the environment and less protein fermentation in the hindgut.

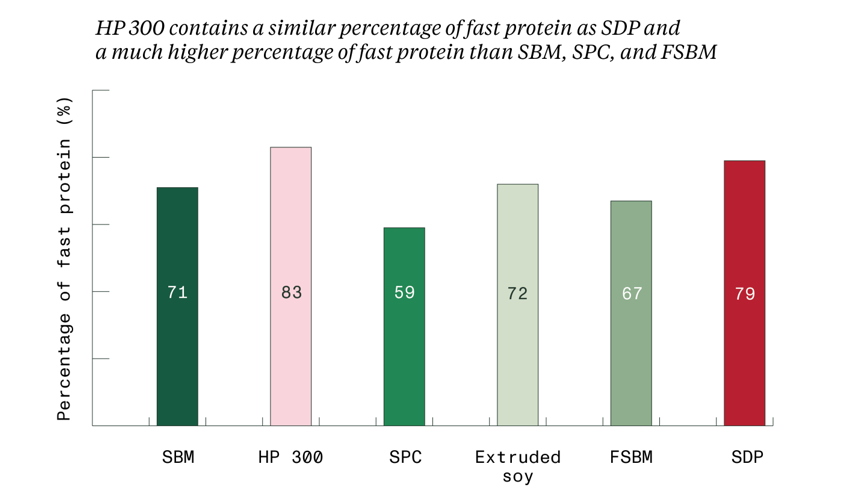

The unique production process of Hamlet Protein improves the kinetics of the protein, resulting in a very fast protein source. HP 300 hydrolyzes faster than protein from SBM and a lot faster than protein from soy protein concentrates (Bible et al., 2023). When compared to SDP, which is generally considered a fast protein source, HP 300 can be digested just as fast making it the fastest vegetable protein source on the market (Figure 1). Other soy-based protein sources are a lot slower and cannot meet the hydrolyzation speed of SDP.

Vegetable plasma can equal growth performance of spray-dried plasma

HP 300 is often referred to as ‘vegetable plasma’ due to the unique characteristics that closely resemble those of SDP:

- consistent and very low level of ANFs

- high digestibility

- very fast protein kinetics

- high palatability

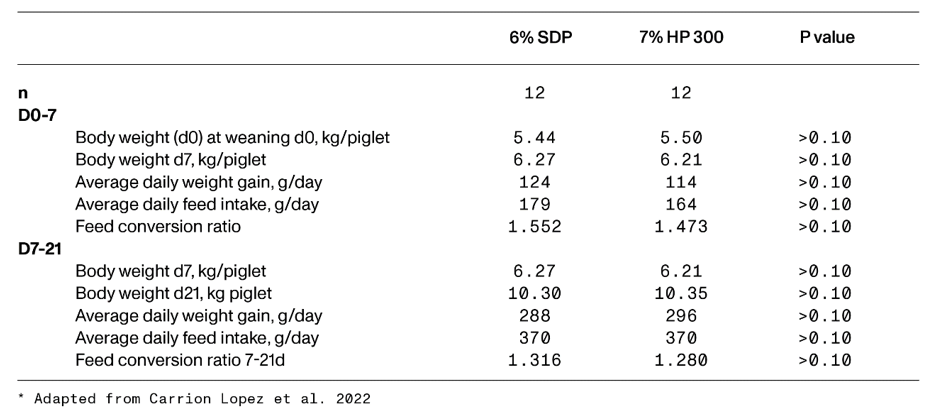

Due to the similarity between the two products no differences in growth performance of nursery pigs are found between SDP and HP 300 (Table 1).

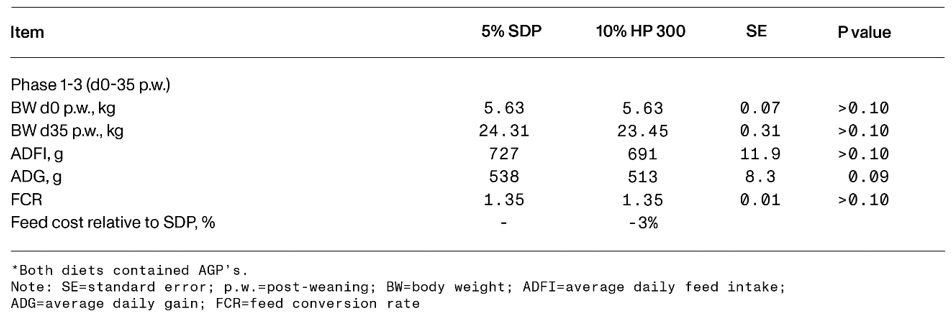

There is a big advantage of replacing SDP with vegetable plasma. The replacement of SDP with HP 300 results in a reduction of total feed costs at equal performance (Table 2).

Vegetable Plasma

The combination of extremely low levels of anti-nutritional factors with a fast hydrolysable protein makes HP 300 an excellent vegetable alternative to SDP while allowing for a reduction in total feed costs.

| References | ||||

|---|---|---|---|---|

| Bible, M.R.; Rasmussen, P.; Rasmussen, S.H.; Blanch, A.; van Leeuwen, J.; Lærke, H.N.; Hedemann, M.S. 2023. In vitro evaluation of protein kinetics of soy-based ingredients. ASAS-CSAS-WSASAS Annual Meeting | ||||

| Carrion Lopez, M.J.; Laguna, A.V.; Rasmussen, S.H.; van Leeuwen, J. 2022. Weaning without zinc supplementation using enzymatically treated soybean meal removes the need for blood plasma in the diet. Zero Zinc Summit 2022, Copenhagen, Denmark. | ||||

| Mercier, S., Breuille, D., Mosoni, L., Obled, C., Patureau Mirand, P., 2002. Chronic Inflammation Alters Protein Metabolism in Several Organs of Adult Rats. Nutrient Metabolism. 132(7):1921-1928 | ||||

| Pasick J, Berhane Y, Ojkic D, Maxie G, Embury-Hyatt C, Swekla K, Handel K, Fairles J, Alexandersen S. Investigation into the role of potentially contaminated feed as a source of the first-detected outbreaks of porcine epidemic diarrhea in Canada. Transbound Emerg Dis. 2014 Oct;61(5):397-410. | ||||

| Perez-Bosque et al., 2016. Spray dried plasma as an alternative to antibiotics in piglet feeds, mode of action and biosafety. Porcine Health Management 2:16 | ||||