To make the invisible visible: Thermography to assess intradermal needle-free vaccination in piglets

Intradermal needle-free vaccination has become an interesting way to tackle many of the challenges the swine industry is facing these days. From biosecurity-related aspects to animal welfare, the intradermal route via a needle-free device could play a key role in improving all these aspects, whilst ensuring similar or improved efficacy compared to conventional routes1.

When talking about biosecurity, contaminated needles have been proven to transfer pathogens (such as PRRSV2) between pigs, which is an element of concern when drafting the internal biosecurity protocol. The absence of needles can help to reduce the spread of disease from infected to uninfected animals within a herd or farm, once the pathogen is already present.

With regard to animal welfare, comparable studies have been conducted to measure the pain or stress of a pig and suggest that the overall pain and stress associated with receiving an injection with a needle are reduced when an intradermal needle free injection device (NFID) such us Hipradermic® is used. It concludes that Hipradermic® reduces behavioural indicators of pain compared to IM vaccination with a needle and represents an alternative for improvement of animal welfare on swine farms3. In fact, NFID users within the swine industry support that approach. For Dr. Erika Romerde, farm veterinarian in The Philippines “less stress is observed in the animal when using it”. Lowering the pain and stress of pigs in production has been shown to increase their general health and growth capabilities4.

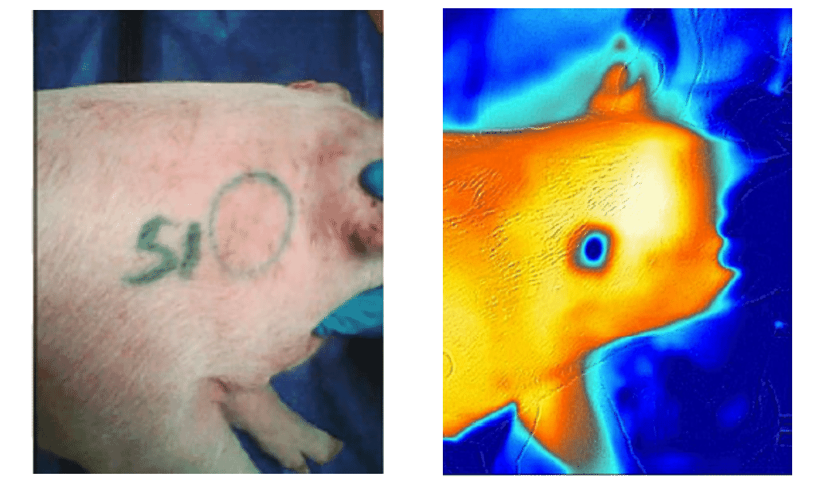

The use of needle-free jet injectors such as Hipradermic® can aid producers in different ways, as already highlighted above5. However, after application of vaccines into the dermis layer, the injection site is sometimes barely visible in piglets, which is an element of concern for new users. One of the simplest techniques available to visualise vaccine deposition after intradermal administration, is thermography.

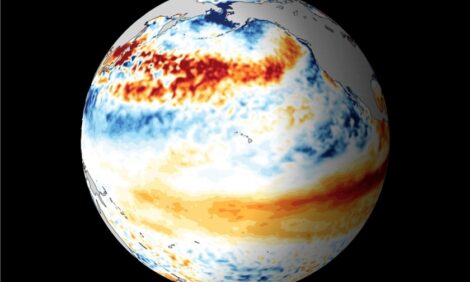

Thermography is a non-contact, non-invasive technique that detects surface heat emitted as infrared radiation. Infrared thermography uses thermal radiation emitted by objects to visualise and measure their surface temperature. The colours of the images represent different temperatures, highlighting hot and cold spots and showing a map of the thermal distribution of a body surface.

Intradermal inoculation with a vaccine involves the alteration of the homeostasis of the inoculation site, modifying the normal thermal distribution of this area. Therefore, the use of a thermal camera would make it possible to observe differences in temperature distribution due to vaccine deposition.

Piglet intradermally vaccinated with the needle-free jet injector, Hipradermic®. The inoculation site can be difficult to detect. Thermal footprint of the vaccine applied intradermally with Hipradermic®. The inoculation site is clearly visible using a thermal image.

As shown with these images, this technique successfully shows the injection site, as the area where the vaccines are located is colder compared to surrounding areas. As time passes, the difference in temperature between the vaccine and the dermis decreases, making it less visible. To properly identify differences in temperatures, a thermal photo should be taken shortly after vaccination.

Thermography cameras are readily available on the market and such cameras are an easy-to-use, low-cost solution to visualise intradermal vaccine deposition.

This technique is a useful way of demonstrating the vaccination performance of an intradermal needle-free device in piglets, of particular relevance when carrying out training for new users.

Intradermal needle-free devices such as Hipradermic® can bring a number of improvements and help to deal with some important challenges for the swine industry, from animal welfare to effective time management and iatrogenic transmission of diseases. Nevertheless, it is important that new users feel confident about the technique that they are performing. By being able to detect the thermal footprint of the intradermal vaccine deposition, users can have “peace of mind” whilst embracing the benefits of the intradermal vaccination.

For references please contact HIPRA.

Acknowledgements: Scientific Marketing Unit in HIPRA