Swine Farm Management: Tackling ASF through effective feed strategies

Learn about control measures to mitigate the impact of ASFAfrican Swine Fever (ASF) has become a significant challenge for swine farm management globally and continues to persist in Asia Pacific. With numerous outbreaks affecting pig populations across the region, ASF poses a severe threat to the swine industry and food security. Effective management and control measures are crucial to mitigate the impact of this disease.

ASF is a viral disease that affects domestic and wild pigs. The virus is primarily transmitted through direct contact with infected pigs, their tissues, blood, or secretions, and also indirectly through contaminated materials like feed, equipment and vehicles. The epidemiological scenarios differ across regions due to variations in virus virulence and host immunity.

ASF's high environmental resistance and ease of transmission via direct or indirect contact exacerbate its spread. As a result, feed has been repeatedly evaluated as a potential vector and its management can play a critical role in mitigating disease transmission.

Dr. Francisco Domingues, Anitox Technical Director for Swine, answers leading questions highlighting the disease's implications a the rigorous control measures, including feed hygiene, essential for mitigating its spread.

Understanding the impact of ASF on swine producers

The consequences of ASF contamination are severe and include high mortality rates among infected pigs, significant economic losses for farmers due to the culling of animals and the subsequent disruption of production, and trade restrictions that can affect the broader pork industry.

Dr. Domingues explains, “Recovery from ASF contamination typically requires extensive decontamination and biosecurity measures, and it can take several months to a few years for a farm to fully resume operations and rebuild its pig population. Unfortunately, the economic losses are very significant and can cost as much as $7,000,000 to restock a 10,000 sow farm.”

In the event of contamination, producers must thoroughly review all aspects of their biosecurity system to minimize the risk of a new outbreak. This includes not only the traditional components such as the movement of people, trucks, animals and supplies but also considering feed as a potential threat, as it has been proven to be a fomite for viruses that can introduce diseases to farms. Therefore, implementing and establishing feed mill biosecurity and feed biosecurity has become a fundamental part of any sustainable swine production system today.

Can ASF survive in feed?

“Yes, ASF can survive in feed, particularly if the feed contains pork by-products derived from infected animals or if it has been contaminated with bodily fluids or tissues from infected pigs,” says Dr. Domingues “As a result many producers formulate plant-based diets, however, studies such as Dee et al., 2020 have shown that virus can remain viable in various plant-based ingredients for varying periods depending on temperature and moisture factors.”

“Over the years the quest for answers has evolved. Two publications from Niederwerder et al. in 2019 determined that under transoceanic shipment conditions, ASF has a half-life in feed ranging from 9.6 to 14.2 days and has a minimum infectious dose of 104 TCID50.”

What are effective strategies for preventing ASF contamination in feed?

“Several strategies have been evaluated to eliminate or to reduce the virus concentration in feed and raw materials, including extended holding time, spray drying, heat treatment and ultraviolet irradiation,” answers Dr. Domingues, “However, recent work by Balestreri et al., 2024, has demonstrated that heat treatment at 100°C degrees for 60 minutes may not reduce the virus to levels under the minimum infection dose in feed.”

Controlling virus transmission during feed production and handling is complex and the success of many methods require extra storage capacity and are subject to variation such as environmental temperature, the type of raw material and feed composition. Chemical mitigants, including feed sanitizers, have been evaluated against a range of swine viruses and evidenced as an efficient and consistent solution to secure greater levels of virus control during the processing and handling of potentially contaminated feed or raw materials. Additionally, feed sanitizers, such as Termin-8 and Finio, offer extended protection against recontamination for at least 14 days, ensuring feed remains protected until the point of consumption.

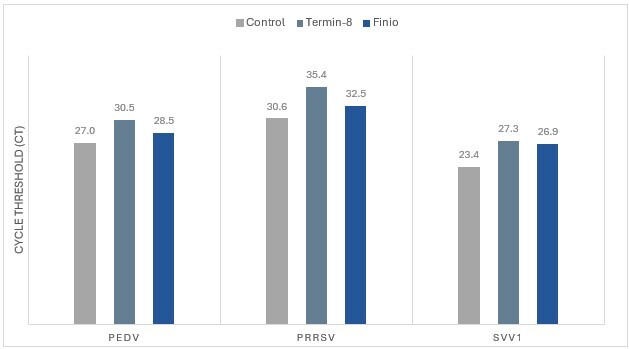

“Throughout the last decade researchers have demonstrated the effectiveness of feed sanitizers against PRRSV, PEDV, and Seneca-virus A (SVA), which is used in place of ASFV to model its behavior. In 2020 and 2024 Dee et al. assessed the performance of feed sanitizers in trials that were capable of detecting viruses in biological samples, observing clinical infection symptoms, and monitoring overall animal performance. Both trials revealed that pigs consuming feed treated with a feed sanitizer showed lower infection rates, improved clinical condition, and increased weight gain compared to the control group. Latest experiments conducted by Kansas State University found that Termin-8® and Finio® reduced the detectable levels of PEDV, PRRSV and Seneca Valley virus 1(SVV1) in contaminated soybean meal when applied prior to or after virus contamination of feed,” says Dr. Domingues.

Figure 1. Impact of Feed Sanitizers on Viral RNA When Applied Post-Inoculation

How do feed ingredients pose a risk to feed biosecurity?

“Various studies have shown that different viruses require different storage times and environmental temperatures to be inactivated. Given the variety of viruses (ASF, CSF, FMD, PED, PRRS, SVA) that can survive for several days under varying temperatures, it is clear how contaminated raw materials pose a significant threat to feed mills and established biosecurity systems,” says Dr. Domingues.

Feed is ubiquitous, sourced globally, and travels as separate ingredients from ports to feed mills. Finished feeds then move from mills to operations, coming into contact with trucks, bins, and feeders before being consumed. To prevent pathogen introduction into live production, feed treatments and interventions must protect against contamination from production to consumption.

Termin-8® and Finio® have been shown to effectively reduce viral contamination in feed and provide long-lasting protection against recontamination, safeguarding feed from viral and bacterial challenges until consumption. Effective feed sanitation is crucial in preventing the spread of swine viruses and ensuring herd health and productivity, making it an essential component of comprehensive biosecurity programs in swine production operations.

To learn more about how feed sanitation can protect herds from viral contamination and optimize pig performance, visit www.anitox.com.