Role of Dietary Fibre in Diets for Growing Pigs - Part 2

Optimising nutritional efficiency has become more of a challenge as modern feed formulations contain more sources of fibre, so Zhimin Huang and colleagues from the University of Minnesota produced this report looking at improvements in artificial feed digestibility measurements.The challenge arises because there is large variation in energy and nutrient digestibility between feed ingredients and even within sources of the same feed ingredient.

Variation in nutrient digestibility reduces nutritional efficiency, increases necessity of safety margins, and increase cost of swine feeding programs. The reason of this variability is that many agriculture co-products, such as distillers dried grains with solubles, contain high concentration of total dietary fibre.

Fast, accurate, and inexpensive nutritional tools are needed to measure variability in nutrient digestibility among co-products and capture full feeding value of fibrous ingredients.

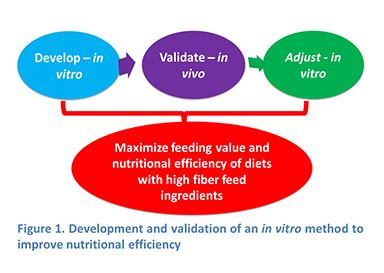

These techniques require development, validation, and adjustment to fit swine feeding programs (Figure 1). Some of these fast and inexpensive tools rely on measuring in vitro (in the test tube) fermentation kinetics.

The most common technique, the three step in vitro method, has been used to predict in vivo energy and DM digestibility of swine feed ingredients and diets (corn soybean, sugar beet pulp, oat hulls, barley diets, and wheat diets).

However, there are no data of the use of in vitro gas production technique for prediction of the concentration of digestible energy and nutrients among sources of corn distillers dried grains with solubles. In addition, there are no data specifically comparing results from the test tube (in vitro) with results measured feeding pigs (in vivo).

Distillers dried grains with solubles have high concentration of insoluble dietary fibre.

These types of dietary fibres tend to be less fermentable than soluble dietary fibres, while data exists on the precision of in vitro techniques on prediction of fermentation of soluble and insoluble sources of fibre, there are no data on the fermentation of sources of insoluble dietary fibre such as corn distillers dried grains with solubles.

Therefore, the objectives of the study was to:

- develop, evaluate, and deliver nutritional tools for the measurement of in vivo energy and nutrient digestibility of different sources of 3 fibrous ingredients;

- test fermentability kinetics differences of wheat straw, soybean hulls, and corn distillers dried grains with solubles.

Materials and Methods

These experiments were funded with contributions from the National Pork Board. Animal experiments were approved by the Animal Use and Care Committee at the University of Minnesota.

In vivo animal experiment

We collected 3 different high fibre feed ingredients and 3 sources of each ingredient: wheat straw (sources 1-3), soybean hulls (sources 4-6), and corn distillers dried grains with solubles (sources 7-9).

Growing pigs (n = 36), with initial body weight of approximately 198 lb (17 weeks age), were housed at the Southern Research and Outreach Center in Waseca, MN. Pigs were individually housed in metabolism cages and allotted to 4 blocks with 9 pigs in each block.

The experiment used a changeover design. Each of the 9 growing pigs in a block were fed 1 of the 9 different experimental diets (Table 1) in 2 consecutive 13-day periods, each of which consisted of 10-day adaptation period to allow the pigs to become accustomed to the cages and to the new diets and a 3-day period during which urine and faeces were collected.

The 9 diets were composed of 3 different sources of each of the 3 high fibre ingredients. The direct procedure was used to measure apparent total tract digestibility of dry matter, gross energy, and total dietary fibre in the diets.

In vitro gas production technique

We adapted the 3-step enzymatic and microbial fermentation procedure to hydrolyse and ferment the 9 samples. The experiment was conducted in Dr. Marshall Stern's nutrition laboratory at the University of Minnesota St. Paul campus.

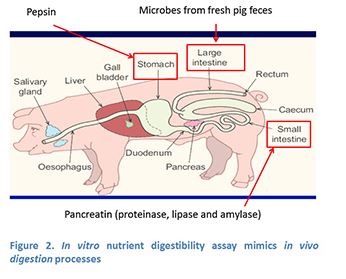

The 3 step enzymatic procedure mimics gastric and small intestine digestion processes using a combination of hydrochloric acid, pepsin, buffers and pancreatin (Figure 2).

Samples were hydrolysed using pepsin for 2 h and pancreatin for 4 h, the hydrolysed residue, was then used for the fermentation step. We measured the amount of gas produced during fermentation at 0, 2, 5, 8, 12, 16, 20, 24, 30, 36, 48 and 72 h.

The gas production was modeled by PROC NLIN in SAS (Version 9.3; SAS Inst. Inc., Cary, NC) based on monophasic model from Groot et al., (1996): G = A / [1+ (BC/tC)], where G (ml/g DM substrate) denotes the amount of gas produced per gram of dry matter incubated, A (mL/g DM) represents the asymptotic gas production, B (h) is the time after incubation at which half of the asymptotic amount of gas has been formed, C is a constant determining the sharpness of the switching characteristics of the profile.

Results

There were significant differences (P < 0.01) in apparent total tract digestibility of dry matter, gross energy, and total dietary fibre among wheat straw, soybean hulls, and corn distillers dried grain with solubles.

Soybean hulls had the greatest apparent total tract digestibility of dry matter, gross energy, and total dietary fibre, which was followed by corn distillers dried grains with solubles and the least values were observed in wheat straw.

There were no differences in apparent total tract digestibility of dry matter among sources of each of the 3 ingredients. There were small differences in apparent total tract digestibility of gross energy among sources of wheat straw, but not among sources of corn distillers dried grains with solubles or soybean hulls.

Among sources of corn distillers dried grains with solubles, source 9 had the least apparent total tract digestibility of total dietary fibre (36.0 per cent), followed by source 7 (43.1 per cent), and finally source 8 (49.8 per cent).

Observations of asymptotic gas production (A) among feed ingredients were in agreement with in vivo observations, where the asymptotic gas production of soybean hulls was greater (P < 0.01) than corn distillers dried grains with solubles and corn distillers dried grains with solubles was greater than wheat straw.

We did not observe differences for time to reach half of asymptotic gas production (B) and the gas curve shape (C) among wheat straw, corn distillers dried grains with solubles, or soybean hulls.

There were no differences in gas production kinetics among sources of any of the 3 ingredients. We observe good correlation (r > 0.7; P < 0.01) between A and apparent total tract digestibility of dry matter, gross energy, and total dietary fibre.

There was also good correlation (r > 0.8; P < 0.01) between B and apparent total tract digestibility of dry matter, gross energy, and total dietary fibre. However, there were no correlations between C and apparent total tract digestibility of dry matter, gross energy, and total dietary fibre.

In conclusion, feeding high fibre feed ingredients to pigs not only reduces the apparent total tract digestibility of gross energy, dry matter, and total dietary fibre; but also there are significant differences among feed ingredients.

The 3 step in vitro dry matter digestibility and gas production technique is a fast, inexpensive, and accurate method that can predict energy and nutrient digestibility among high fibre feed ingredients.

Nutritionists using this tool can increase sustainability by using high fibre feed ingredients and increasing nutritional efficiency of swine feeding programs.

However, the in vitro technique was not accurate in predicting digestibility of energy and nutrients among sources of corn distillers dried grains with solubles. Therefore, modifications to the technique are necessary.

September 2015