Pig Pen Design is Key to Optimum Performance

Silence, or something close to it, is a wonderful thing to hear in a sow gestation barn. It’s the sound of productivity, and one that many pork producers incorrectly assume they can’t achieve.“It’s hard for many people to imagine how calm sows can be in a well-designed group housing system” says Graydon Bell, sales manager for Nedap U.S.

“We have learned that a key to creating a calm atmosphere is preventing sows from re-entering feeding stations immediately after exiting. With this fact as a foundation, we can design pens to fit facilities of all sizes and styles of group housing.”

In addition to thoughtful pen design, managing sows individually within the group is a key to maximizing productivity.

One of the most efficient means of individual management is electronic sow feeding (ESF). This practice can help producers overcome two perceived challenges of group housing: sow aggression and inefficient feed intake. Using these tools, producers can expect to see measureable returns on investments.

“Linking electronic identification to feeding allows producers to monitor the feed intake of gestating sows and feed each sow according to her requirements,” Bell says.

“In this way, we ensure that each sow is fed correctly to meet her nutritional requirements according to her parity and body condition. This prevents feed waste and leads to improved condition and sow performance.”

Designed for success

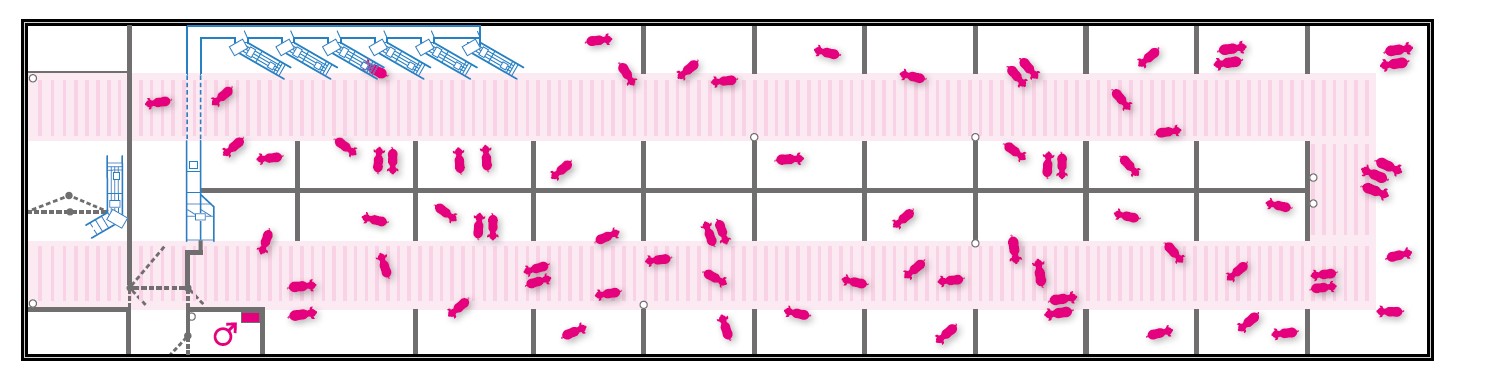

Well-designed pens can accomplish much because they direct sow flow in a way that can reduce aggression and promote healthy movement. When designing group housing, consider function and space.

Whether producers choose to use dynamic or static groups, the design should include four distinct types of space to meet sows’ basic needs.

- Sleeping and resting areas

- Feeding area

- Space to access water, expel waste and be exposed to heat detection technology

- Activity area such as alleys wide enough that animals can pass without aggression

Directing traffic

The foundation of smooth pig flow is designing pens so sows exiting a feeding station cannot immediately access the entrance to the feeding station. Operations that are designed properly direct the sow exiting the feeding station to walk the entire length of the pen up and back before returning to the feeding station. These operations experience measurably less vulva biting and fewer skin abrasions among sows.

Ideally, the activity area or walking space encourages pigs to move away from the feeding station and past the resting areas before returning to the feeding station. This encourages exercise, and, once a sow sees her resting area, she often will lay down instead of completing the return walk to the feeding station.

Practice makes perfect

Complete training of gilts and new sows leads to better function of group housing and ESF.

Successful gilt training includes getting gilts comfortable with the entrance and exit gates prior to moving them through feeding stations. The best employees for this job are the ones who are patient enough to let the gilts and sows train themselves as much as possible.

“You have to help them, but you have to give them time to find their way, too,” Bell says.

“Otherwise you’re going to end up with pigs who are dependent on people to find the feeders.”

Gilts can start being prepped for ESF very early in the gilt developer unit by exposing them to the gates. Gilts should use training stations for a minimum of one to three weeks.

November 2015