Now is the time to rethink soybean meal net energy in pig diets

Pig genetics have advanced. Do your pig diets reflect those changes?Editor’s note: Hans Stein, PhD and professor of nutrition at the University of Illinois, and Aaron Gaines, PhD and managing partner at Ani-Tek LLC, spoke at the Iowa Swine Day pre-conference symposium titled Soybean Meal 360°, expanding our horizons through discoveries and field -proven feeding strategies for improving pork production. The event was sponsored by Iowa State University and U.S. Soy.

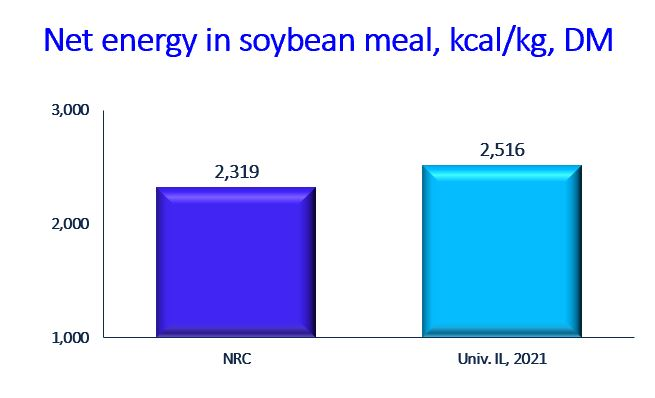

The National Research Council (NRC) requirement for soybean meal net energy in pig diets was calculated more than 30 years ago and indicates that the net energy of soybean meal is 77% of corn’s net energy value. A lot has changed in pig production over the last 30 years, so a group of researchers and nutritionists across academia, industry and commercial operations has conducted studies to re-evaluate if the NRC book value for soybean meal net energy still applies to today’s pig diets.

Dr. Stein and colleagues have conducted several studies at the University of Illinois to determine the net energy in soybean meal.

“Over many years, we have consistently seen higher net energy values from soybean meal than what the NRC book values would indicate,” said Dr. Stein. “Our 2021 research showed an increase of almost 200 kcal/kg when compared with the NRC book value.”

At the same time, a similar study was conducted in China, and their research indicated a little bit higher value than the University of Illinois research showed.

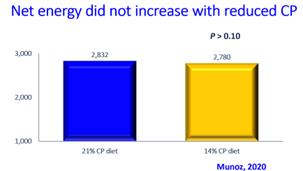

“We repeated our research and got the same value again but thought that maybe there was something in our system that didn’t work or that we didn’t understand, so we compared low-protein diets versus high-protein diets,” he said. “When you have low protein in the diet or low soybean meal, then you have more corn. If corn has greater net energy than soybean meal as the NRC book value suggests, then we should get a greater net energy value in a low-protein diet.”

However, the research didn't show a difference between low-protein and high-protein diets (Munoz, 2020). The net energy values were similar, indicating the two ingredients are basically the same in terms of net energy.

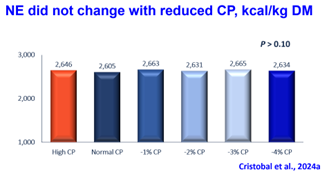

Next, Dr. Stein conducted the study (Cristobal et al. 2024a) comparing multiple diets including a high-protein diet with 27% soybean meal and a normal 19% soybean meal diet with more corn and crystalline amino acids; then they gradually took down the soybean meal to 17%, 14%, 12%, and 9% while increasing corn and crystalline amino acids.

“If you believe NRC, we should see a linear increase in net energy in these diets as we reduce protein and reduce soybean meal,” he explained. “However, the net energy values show there’s absolutely no difference between the low-protein diets and high-protein diets. The only way to interpret this is that there's about the same amount of net energy in corn as there is in soybean meal.”

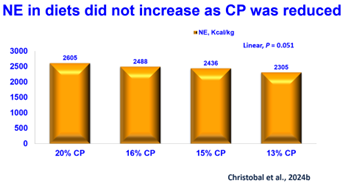

Dr. Stein utilized another approach to determine net energy using the comparative slaughter procedure (Cristobal et al. 2024b), where a group of pigs are slaughtered at the start of the study, then another group of pigs are fed different diets for four or six weeks. Then those pigs are slaughtered and tested to determine how much actual energy grew in the body of the pig and comparing the results to the first group of pigs.

“The results showed absolutely no increase in net energy as crude protein was reduced. If anything, there was a tendency for a decrease in net energy when we reduced soybean meal in the diets,” he said. “So, having a net energy in soybean meal that is lower than in corn, just does not make sense. When we reduce soybean meal, we do not see an increase in net energy which we should. Coming back to the NRC book value, saying that corn has a value that's relatively high, and net energy soybean meal is 77% of that value is not what we see in our research experiments.”

How was the NRC value developed?

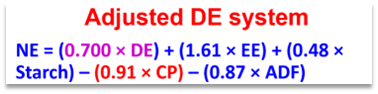

Dr. Stein said it is notable that the NRC low soybean meal net energy value is the same for many countries such as France, the Netherlands, Brazil, etc. because the data comes from pretty much the same source and thus has the same conclusion. The equation used by NRC is called “adjusted DE equation”.

The important part of the Adjusted DE (Digestible Energy) System equation is the huge negative value it places on crude protein, which means if you have more crude protein in the diet, then you get a reduced calculated value for net energy.

“In fact, there's a little bit more digestible energy in soybean meal than in corn, but because of that huge negative value for crude protein in the equation, the calculated net energy is much lower for soybean meal than for corn.

Why the change in soybean meal net energy?

One reason for the increased net energy we now measure for soybean meal may be that modern pigs have much greater nitrogen retention than pigs had 30 to 40 years ago when the work to develop the equation used by NRC was conducted. In fact, whereas pigs used 40 years ago had a nitrogen retention of 40% to 45%, modern pigs have a nitrogen retention close to 70%. Thus, a greater part of the amino acids in soybeans are directly used for protein synthesis in the pig.

Because amino acids used for protein synthesis have a greater energy efficiency than amino acids used for other energy purposes after being deaminated in the pig, the energy of the protein fraction in feed ingredients is increased. This explains why high protein ingredients such as soybean meal have greater net energy today than they had 40 years ago, and the equation with the negative impact of protein on net energy, may therefore, no longer be accurate.

Bottom line, Dr. Stein said the net energy in soybean meal under academic circumstances is at least between 90% to 100% percent of the net energy in corn which is quite a bit higher than current NRC book values of about 77%.

“We have much more efficient pigs today, and they utilize protein much more efficiently than the pigs we had 30 to 40 years ago. It’s not that they were wrong when they did those experiments in the 1990s,” he said. “It's just that now we have different, more lean, more efficient pigs and they utilize the protein fraction of the diet much more efficiently than they used to.”

Soybean meal net energy in a commercial environment

Dr. Aaron Gaines shared studies and observations on soybean meal energy values in a commercial production environment.

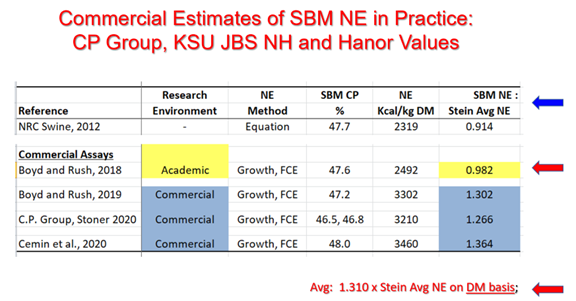

“The commercial side of the story really starts with some work and experiments that Dr. R. Dean Boyd did at the Hanor Company to validate academic energy estimates,” said Dr. Gaines. “The first study was conducted in a commercial environment, but the environment was more like academic conditions in terms of stocking density with 8 pigs per pen (2 barns per site; 480 pigs/barn) and high health status. They found the relative energy value of soybean meal relative to corn NRC values on a dry matter basis of about 82%, and the good news from that first study was it was in very close agreement with the work of Dr. Stein in his lab and within 1% of the university estimate.”

A second confirmatory study by Drs. Boyd and Rush in 2019 showed a little different result. They found a net energy value relative to corn of 109% which is 30% higher than their first experiment. “At the time, they didn't believe it and put that data into an archive, never to see the light of day until recently. Of note in the second study, the conditions were more commercial in terms of pen density (i.e. 25 pigs/pen; 1250 pigs/barn) and pathogen load,” he said.

The Snyder growth assay methodology is used in commercial experiments and has been used for 40 years to validate net energy estimates for feed ingredients as well as to recalibrate the equations and energy prediction equations. More recently several companies have used a similar assay referred to as productive energy since it measures growth.

“It's really the amount of energy that's utilized for growth in these growth assays. You feed increasing levels of the test ingredient in relation to a known ingredient such as corn,” he said. “If your estimate is correct as you increase the level of soybean meal, caloric efficiency will be equal across the diets, so there will be no change in slope. However, if there is a difference in caloric efficiency, either high or low, that means your estimate is not correct and you’ll need to do some calculations to correct it.”

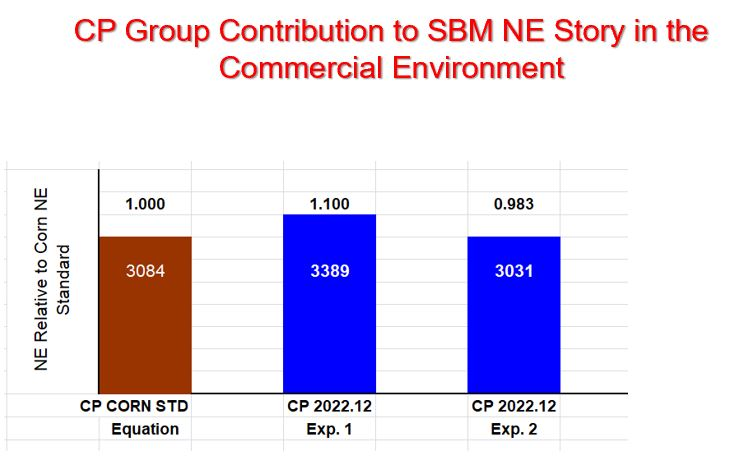

Working with Charoen Pokphand’s (C.P. Group) Dr. Gary Stoner, the first study was a grower pig study, and the second was a finishing study utilizing 800 pigs with 18 to 19 pigs per pen and four different levels of soybean meal at a commercial research facility.

“The first study with grower pigs showed a value of 110% of their corn standard. In the late finishing period, the C.P. Group study found a relative energy value of 98% of corn,” he explained. “This was encouraging, especially for Dr. Boyd who went back to the data archive and dug out his work study, because the studies corroborated his early study, showing that the soybean meal energy value was indeed greater under commercial conditions.”

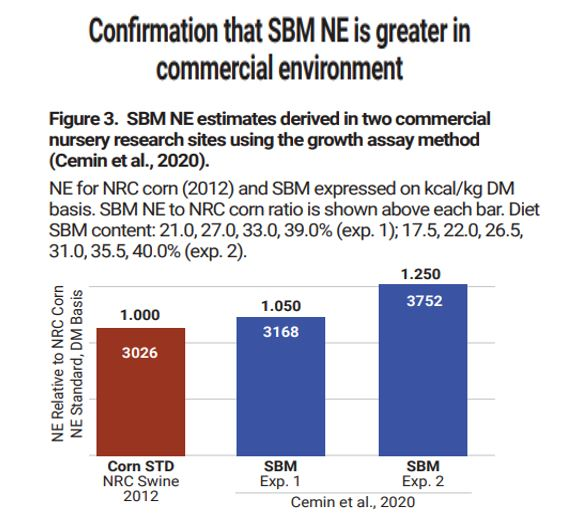

Dr. Gaines also looked at data in the private sector done in collaboration with Kansas State University and JBS Live Pork (Cemin et al. 2020) with about 6,000 nursery pigs between the two studies.

“In the first study, they found a relative net energy value of 105% of corn. In the second study, they found a net energy value of 125% of corn,” he said.

“When you look at these commercial estimates of soybean meal in practice, the 2018 study by Boyd and Rush was done in a commercial environment, but the conditions were more academic-like, and the results are in close agreement with Dr. Stein's estimate of 98%. In the other studies, we find the value that's about 31% higher than what Dr. Stein's lab reported.”

“This doesn't mean that Dr. Stein's estimate is wrong; it's telling us that under commercial conditions when there's higher stocking density and perhaps more pathogen load, the traditional method of determining energy doesn't fully account for what's happening with soybean meal,” he said. “An important conclusion from these commercial studies is that the results are very repeatable. Five studies, four locations, three companies. And subsequent to this work, there's been a lot of companies that have looked at soybean meal net energy value and have found similar results. And remember that this doesn't apply just to health-challenged pigs; it applies to commercial pigs in general.

What value should you use in practice?

“In terms of energy value of soybean meal on a dry matter basis, 95% is fairly common,” said Dr. Gaines. “However, we're seeing some corporate movement where companies have tested this for themselves, and they're moving up to 100-110% of corn on a dry matter basis.”

An industry survey of the top 11 pork powerhouses, which includes about 3 million sows and makes up about 49% of the industry, showed that, on average, their energy value relative to corn on an as-fed basis was 97%. On a weighted basis, the results were the same at 97% with a minimum value of 87% and a maximum value of 105%. Dr. Gaines noted that the differences could be influenced by the system's corn in terms of particle size and moisture content.

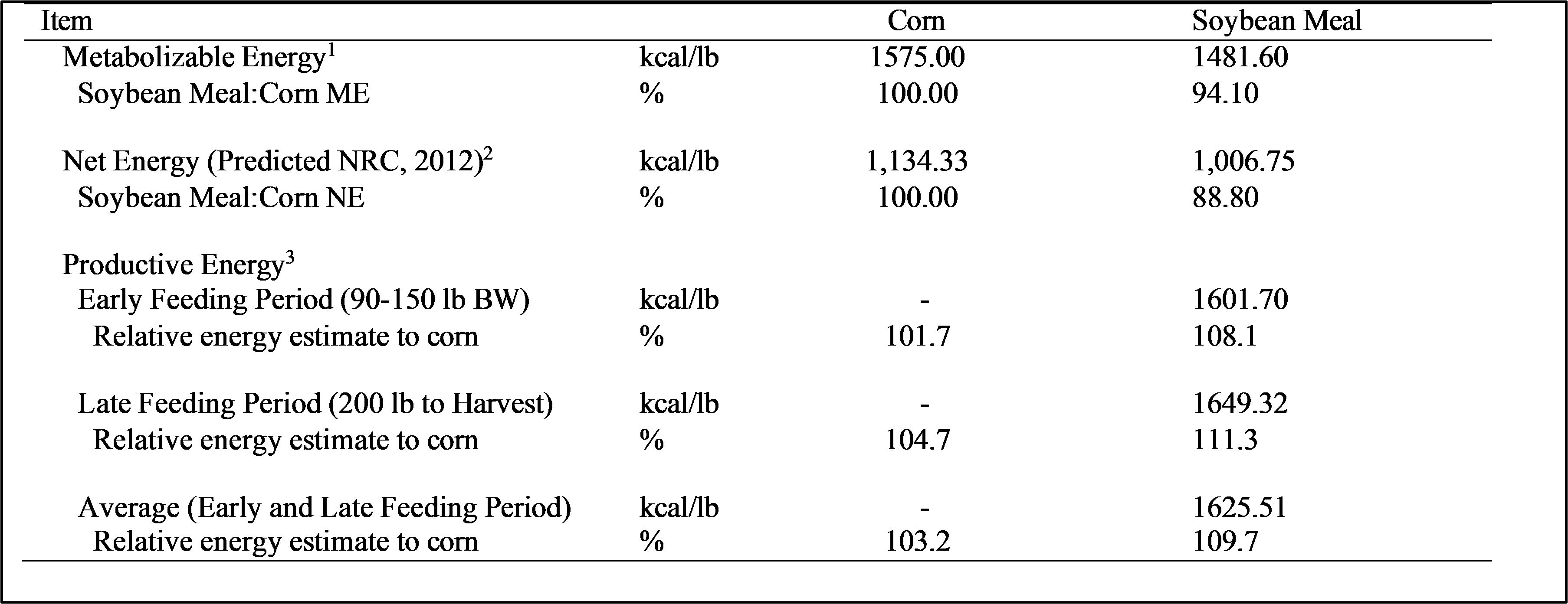

“About half of the powerhouse companies have done their own internal evaluations, which takes me into this next study. The Maschhoffs have conducted a couple studies looking at soybean meal net energy with support from the United Soybean Board. The study included 2,720 pigs with 20 replicates per treatment group. They had two feeding periods – early (90-150 lbs.) and late finishing (200-295 lbs.).

In the early feeding period, soybean meal levels went from 21.6% in the low soybean meal diet with 0.38% L-lysine HCl. The high soybean meal diet had up to 34.3% soybean meal and no crystalline lysine.

In the late finishing period, the low treatment was at 10.8% soybean meal with 0.31% L-lysine HCl. The high treatment went up to 21% soybean meal and no crystalline lysine.

“In this experiment, they attempted to make the diets isoenergetic, so there were some slight adjustments in fat level coming from yellow grease in the study. In both the early finishing and late finishing period, as soybean meal level increased in the diet, caloric efficiency improved, which tells us they were underestimating the energy value of soybean meal,” he explained. “After making calculation adjustments, they had an estimate of 101.7% of corn, and in the late finishing period, they had a value of 104.7% relative to corn. The combined average of the two periods was 103.2%.” Another important point that Dr. Gaines mentioned was the fact that the corn source used in the study was finely ground (~ 250 microns) given pelleted diets so the relative energy value of soybean meal would be higher if corn was ground to a higher particle size used in meal diets.

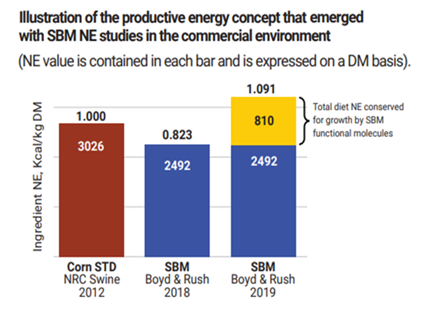

In terms of the proposed concept for elevated soybean meal net energy value in practice, productive energy is a measurement of the total energy that's going toward growth.

“We can usually account for productive energy through classical ingredient energetics like Dr. Stein talked about, but in the case of soybean meal, it appears to be different,” he said. “We can explain about 75% of the energy in soybean meal from classical ingredient energetics, but there's another 25% that is not explained.”

Dr. Gaines said the working hypothesis suggests that there's dietary net energy that's being conserved for growth, which is likely due to some of the bioactive compounds in soybean meal. When considering productive energy in soybean meal, it's the sum of classical ingredient energetics plus the sum of dietary net energy conservation for growth.

“In conclusion, soybean meal net energy values are equal to or 10% greater under commercial conditions relative to NRC corn on a dry matter basis. We're suggesting a soybean meal net energy value of 3,026 kcal/kg, which would be equal to NRC corn, or 10% higher would be 3,328 kcal/kg. If you get into an academic environment or a situation where there's low population densities and lower pathogen load, we’d recommend 2,502 kcal/kg, which would be 83% of corn on a dry matter basis.”

These findings have been validated by academic and commercial production companies. In terms of the mechanism of action, Dr. Gaines says that's not been fully elucidated, but the current work in hypothesis is that the functional bioactive compounds in soybean meal are countering some of the pathogen diversion and we're getting more conservation of that energy directed toward growth.

Click here to learn more.

Brought to you by U.S. Soy. Fully funded by the National Soybean Checkoff.

Reference: Noblet, Jean & Fortune, Herve & Shi, X.S. & Dubois, Serge. (1994). Prediction of net energy of feeds for growing pigs. Journal of Animal Science. 72. 344-54. 10.2527/1994.722344x. https://www.researchgate.net/publication/15040776_Prediction_of_net_energy_of_feeds_for_growing_pigs