Is your farm vulnerable to disease through your feed supply?

Some pathogens may go unnoticed in the production process, while others wreak havoc on an operation.Part of Series:

Next Article in Series >

Porcine reproductive and respiratory syndrome (PPRS), porcine epidemic diarrhea virus (PEDV), classic swine fever (cholera) or African swine fever (ASF) can create significant disease and economic losses or even the loss of the entire pig population. Other pathogens, like Salmonella and E. coli, are zoonotic and pose a risk to human health.

Pathogens can enter the live production process through a variety of routes. People, infected vectors like rodents, insects or birds, or fomites like feed, vehicles or water are just a few pathways that pathogens take advantage of to enter a farm. It is recommended that farms develop a comprehensive biosecurity plan to stop pathogens from ever entering the farm.

© Anitox

“It has been nearly seven years since Dr. Scott Dee examined feed as a potential source of contamination to understand the 2013 PEDV outbreak, and the industry has invested heavily in its understanding of feed as a fomite for viruses since that time,” said Enrique Montiel, DVM and Director of Nutrition and Live Production at Anitox. “This study not only confirmed that PEDV could be recovered from contaminated feed, but that feed was able to act as an infectious vehicle and could be considered a credible biosecurity risk.”

Since then, numerous studies have been conducted to understand feed as a fomite for viruses. Dr. Dee and Dr. Megan Niederwerder at Kansas State University have examined the likelihood of viral transmission via transboundary travel.

“The studies examining viral prevalence in feed during a transboundary model highlighted risk related to specific ingredients and confirmed that ingredients are capable of sustaining a viral load under global shipment conditions,” Dr. Montiel explained. “Additional work done by Dr. Niederwerder has examined the transmission of ASF from feed to pigs, and while the infectious capability of contaminated feed is lower than that of a liquid inoculum in a single exposure, modeling suggests that feed still carries an inherent risk due to the repeated exposure between livestock and feed.”

Understanding the risk diseases pose to the industry is important in the implementation of disease prevention protocols within operations. For example:

- establish a good biosecurity plan

- disinfecting water systems

- establishing well-ventilated buildings

- washing indoor slats, and manure is flushed out of the barn periodically disinfecting the facility between groups of pigs

- vaccinating the herd to prevent disease

- sanitizing feed

“Feed has been recognized time and time again as a fomite for pathogens. It is prudent for the industry to have awareness for how feed introduces pathogens into an operation,” said Dr. Montiel.

Feed plays a role by introducing pathogens two different ways:

- one of the feed ingredients itself is contaminated, or a finished product in the feed that is of acceptable quality but gets infected during the handling process

- feed gets infected through contamination by other fomites or vectors either on the farm or coming onto the farm spreading the pathogen in the herd

Consequences of pathogens entering production facilities

Some pathogens will cause clinical disease symptoms that are obvious to the farmer and veterinarian. However, some pathogens cause subclinical symptoms that go unnoticed and lower pig performance creating an inefficient herd that can never reach its genetic potential.

“All farmers have to deal with some level of pathogens at the farm, and there is always an economic impact due to this exposure to pathogens,” said Dr. Montiel. “It’s important to proactively monitor the flock and stay on top of any changes in feed or water intake and changes in behavior and stress levels of the herd along with regular diagnostic testing of animals to ensure new pathogens aren’t showing up.”

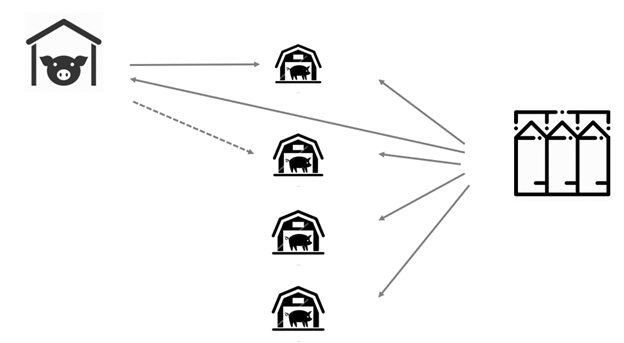

Feed as a fomite can have a significant impact because there are so many ways it can become contaminated with a pathogen. Many operations use automatic feeders that will take the feed from one barn to another to another. Feed can then be a vehicle to spread the pathogen throughout the entire herd. Thus, efforts to sanitize feed will be important for disease prevention and control.

“Different farms have different needs and challenges. However, if you look at what impacts the whole business there are two common sources. One is where the animal is coming from, and the other is the feed that's going to all these barns,” he said. “Pathogen-contaminated feed has a huge impact because it affects all of your barns, all of your farms. One of the principles of how disease occurs is that it starts in one house, in one group of pigs, and then disseminates to the rest. When you see a problem that is evenly widespread across the whole operation on all farms, you've got to suspect that it's the feed because it's being spread systemically.”

There are several ways to sanitize feed and use the treatment as a biosecurity tool for disease prevention. One example is to source quality feed ingredients to assemble your final feed and have those ingredients sanitized at the source, or after they arrive at the feed mill. Disinfection can be a product that is applied to the ingredients, or it may be a physical element like heat. Another option is to sanitize the finished feed after the feed is prepared.

“The biggest difference between using any kind of physical element versus a sanitizer is that a feed sanitizer will provide longer-lasting, recontamination protection as feed is transported, stored and fed to your animals,” he noted. “Whereas a physical treatment like heat or irradiation is a spot treatment – it only cleans it at that moment in time, but the feed can easily be re-contaminated before it reaches the animal.”

Producers wanting to take effective action to protect their herds against virus transmission through feed can get more information at www.anitox.com/pigsite.

Because each farm is different, feed pathogen risks will vary from operation to operation. Watch for our next article in this series that can help you better understand the specific feed risks related to your individual farm.