Increasing Uniformity of Finished Pigs

Variation occurs for many reasons: season, management, nutrition, feeding strategy, genotype, environment, gender and health. It is important that the effort and resources put into producing finished pigs are not wasted at the final stage and that uniformity among pigs being sent to slaughter is maximised.How uniform are your pigs?

It is important to be aware of and understand the variation on your unit. Look at three (or more) months worth of grading information and note the following (there is space on the reverse to do this):

- Overweights

- Underweights

- Out of probe specification pigs

- % of pigs in the optimum box (target 85%)

Note: When looking at grading information choose a period of normal production, ie avoid data collected during movement restrictions, consistent hot periods or Christmas and New Year

Which appears to be your main problem? Discuss what you have found with your marketing company/abattoir buyer to confirm your problem areas.

Setting targets for your unit

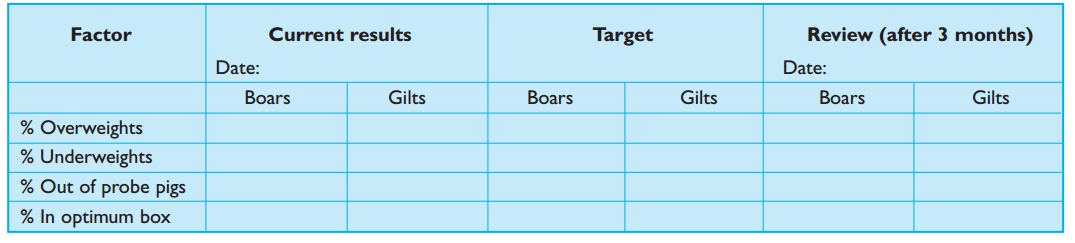

- Note your average deadweight and probe results and set targets relevant to your contract (use the table below)

- Each unit will have different targets, depending on the contract

- You and your staff need to be aware of the current probe and deadweight specifications required by the contract

- Discuss your targets with your marketing company or BPEX KT Manager to clarify what is ‘normal’

- Discuss slaughter data with finishing staff each week/batch so that they can see progress being made and quickly implement changes

- Improving the management of the weaned and growing pigs will reduce variation from the offset

Management guidelines

Weighing pigs

Weighing pigs on a routine basis throughout their lifetime, ie weighing at routine pig moves/flow, gives you essential information that will help you improve uniformity.

The data will let you know when your weight spread becomes out of the norm or if growth rates are slowing. Solving these problems will rectify issues with uniformity early on in the pigs’ life before they extrapolate.

Set out protocols with your vet and nutritionist if variance is found at routine pig moves.This means farm staff can react quickly to any particular problems.

Weight Watcher Pens

Pick out a number of pens from a week/batch of production, weigh these and record average weights. This is an excellent way to gather useful information in a short period of time, it will provide a good indication of growth rates and pre-warn you of slow or fast growing periods. If you group your pigs by size make sure you pick representative pens, from the smallest to the largest pigs.

Gender

- Boars grow faster and can be leaner than gilts

- If your analysis shows gender differences consider different selection weights for boars and gilts

- Depending on the extent of the gender differences it may be worth considering split sexing; talk to your vet and nutritionist about the advantages this may have on your unit

Nutrition and feeding

- Incorrect or inappropriate diet specifications will increase the likelihood of variation in weight and probe measurements. Discuss with your nutritional advisor

- Consistent diet ingredients can reduce variation among pigs fed by-products and home-mixed feed

- Feed to match genetic potential and health status

- With ad lib feeding ensure hopper space is adequate for weight; (50mm/pig, increasing to 75mm/pig near finishing) and hopper design and situation in the pen allows equal feeding opportunity

- With restricted feeding ensure hopper space is adequate; (200mm/pig, increasing to 300mm/pig near finishing) to allow equal feeding opportunity

- With restricted wet feeding allow all pigs to feed at once; look for queuing and vices

Always remember the importance of water: water intake drives feed intake. Clean, constantly available and accessible water is vital to maintain feed intake. As with feed, equal drinking opportunity will reduce variation. Finishing pigs require 5-6 l/day plus water flow rates should be 1-1.5 l/min.

Grading results

Make a note of your current grading figures, set realistic targets and review these in 3 months.

Genotype

If you are producing your own replacement gilts there will be a percentage of dam line progeny in the finishing herd; these will probably introduce variation in both growth and grading results, especially at heavier weights. Identify the correct streaming and sale weight for these dam lines.

Environment

- A poor environment will result in greater variation among pigs

- Spend time observing your pigs’ behaviour, look out for huddling, etc

- All-in, all-out systems are preferable where possible and a strict cleaning and disinfection protocol must be followed

- Keep buildings and ventilation systems in good repair; check for worn bearings, burnt out fans, blocked inlets etc

- Stocking densities above and below the optimum can compromise growth and grading

Overstocking can cause:

- Heat stress

- Unequal feeding and drinking opportunities

- Extended days to sale and pen clearance

- Increased vices (tail, ear and flank biting etc)

Understocking can cause:

- Cold stress, especially in naturally ventilated buildings and buildings with poor temperature control

Health

The better the health the more chance the pig has of achieving its genetic potential. In relation to variation and grading, improved health can:

- Increase growth rates

- Reduce the spread of pig weights within pens

- Reduce the number of condemnations

Seasonal effects

Year on year there is a trend for probe and carcase weights to be lower during the warmer months, and increase going into autumn. Contact a BPEX KT Manager to discuss specific seasonality issues on your unit and what can be done to overcome them.

October 2015