Field Testing a Filter for Disease Control on Pig Transport Trailers

Evaluation of a prototype air filtration system installed on a transport trailer showed that the use of selected microbial filters can effectively capture bioaerosols and prevent entry into the interior or the trailer, report Bernardo Predicala, Alvin Alvarado and Samantha Ekanayake of the Prairie Swine Centre in Canada in the Centre's latest Annual Report.Summary

The spread of airborne transmissible disease such as porcine reproductive and respiratory syndrome (PRRS) continues to be a serious threat to the North American swine industry as this disease causes significant economic losses to infected herds.

This project at the Prairie Swine Centre in Canada aimed to develop an additional line of defence against infection of airborne diseases by designing an air filtration system for a swine transport trailer to maintain a pathogen-free environment inside the trailer during transport.

Testing and evaluation of the prototype air filtration system showed that the use of antimicrobial filters (i.e. MERV 16 and fabric bag filters) can effectively capture bioaerosols in the air and prevent their entry into the animal compartment of the trailer.

Introduction

The growth and success of the Canadian pork industry over the past decades depended significantly on access to highly improved genetics.

High-value breeding stock produced from nucleus and multiplier arms inevitably would need to be transported to the commercial producers, thus putting these valuable genetic stock at risk of exposure to pathogens circulating in the transit areas.

While individual farms have biosecurity procedures to ensure that the delivered animals are not introduced to the herd if infection was detected, the risk of infection of the breeding stock during transport can be significant, particularly during passage through pig dense areas of Quebec, Ontario and Manitoba, where disease outbreaks can still happen despite current biosecurity protocols in place. Thus, it is imperative that measures be developed to protect breeding stock during transport, thereby avoiding infection of these high-value animals and the consequent significant economic loss.

This project’s overall goal was to design, develop and evaluate an air filtration system that can be fitted to a transport vehicle to prevent infection of the high-value breeding stock during transport.

The specific objectives were to fabricate and install a prototype system in an actual transport trailer, and evaluate the performance of the filtered trailer system.

Experimental Procedure

An initial design which included an axial fan, air filtration system (pre-filter combined with high-efficiency filter), air inlets and air exhaust vents with shutter was formulated based on literature review and information gathered from previous and existing filtered trailers.

The components were installed on a commercial swine transport trailer (goose-neck trailer 16 feet body length, 6 feet 6 inches wide and 6 feet high). The air filtration components were fitted in the goose-neck area and was operated using a forced-ventilation system (Figures 1 and 2).

The retrofitted trailer was tested for effectiveness in maintaining a pathogen-free environment inside the trailer during operation of the filtration system. A bacteriophage φX174 (ATCC 13706-B1) which is a benign model used as surrogate for pathogenic microorganisms in filtration studies, was used in this test.

During the actual testing and evaluation, the bacteriophage solution was aerosolised in the goose-neck area of the trailer using a fogging equipment. Air samples were collected upstream (inlet side) and downstream the filtration system (inside the trailer) using a three-piece sampling cassette with mixed cellulose filter (MF-Millipore), and a vacuum pump operated at 2.5 litres per minute flow rate.

Bacteriophage concentrations collected on the sample filters were determined based on amplification of a specific deoxyribonucleic acid (DNA) sequence in the target organism using quantitative polymerase chain reaction (qPCR).

Two types of air treatment filters were tested: MERV 16 with a pre-filter and antimicrobial fabric bag-type filters. Both types of filters are used in air-filtered commercial barn installations.

Th e concentration of bacteriophage φX174 at the inlet area (upstream side) was reduced significantly (p=0.002, n=9) after passing through the MERV 16 filter. The average reduction relative to the upstream concentration was about 89.3 per cent; during the tests, a few instances showed that the MERV 16 achieved a 100 per cent reduction in bacteriophage concentration.

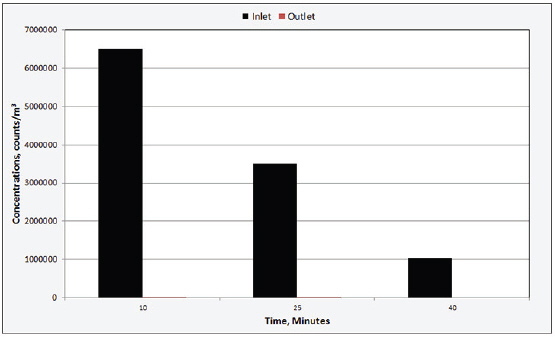

The effectiveness of the fabric bag filter in removing bacteriophage in the air is shown in Figure 3. Similar to MERV 16 filter, the fabric bag filters achieved significant reduction (p=0.02, n=3) in bacteriophage φX174 concentration. Relative to the upstream concentration, the fabric bag filters had an average reduction of about 99.8 per cent.

Comparing the percentage reduction achieved by the two filter types, MERV 16 filters were not significantly different (p=0.695) from the fabric bag filters.

Based on the information gathered from conducting the tests, a number of recommendations were identified to improve the operation and effectiveness of the system. These included creating more openings in the inlet as well as in the exhaust area to reduce the fan static pressure, installation of an environmental controller for better regulation of the temperature inside the trailer, and installation of a temperature monitoring system and carbon dioxide detection system with alarm function that can be detected in the truck driver cab.

Conclusion

Based on the work completed for this project, the following conclusions can be made:

- Using information available from literature and other resources, various design components can be identified and assembled to develop an air filtration system for an existing commercial swine transport trailer to maintain a pathogen-free environment inside the trailer during transport of animals.

- Testing and evaluation of the prototype air filtration system showed that the use of antimicrobial filters (i.e. MERV 16 and fabric bag filters) can effectively capture bioaerosols in the air and prevent entry into the animal compartment of the trailer, thereby protecting the animals from potential infection by airborne transmissible diseases during transport.

Acknowledgements: Funding for this project has been provided in part through Industry Councils from Saskatchewan, Alberta, Manitoba and Ontario which deliver the Canadian Agricultural Adaptation Program (CAAP) on behalf of Agriculture and Agri-Food Canada. Strategic funding provided by the Saskatchewan Pork Development Board, Alberta Pork, Manitoba Pork Council, Ontario Pork and the Saskatchewan Ministry of Agriculture.

May 2015