Eight Dimensions of Pig Feed Intake

Most articles on feed intake in wean-to-finish (W2F) analyze the effects of individual factors, such as water availability, feeder space, energy diet or stocking density on average daily gain (ADG) and feed conversion (FCR). However, it is important that producers understand how different factors that affect feed intake interact with each other and how they can be handled at the "slat" level with a goal of improving pig performance. The objective of this article is to review eight factors that impact feed intake in W2F operations and how these can be managed in the barn.1) Feeder Space

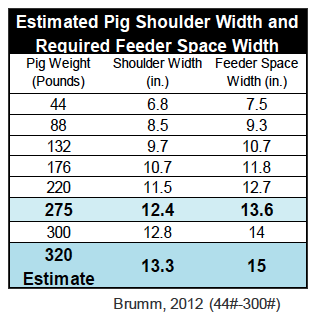

Although many feeders have some type of feeder space division, they may not accurately reflect the true space requirements. Both pig weight and shoulder width determine the appropriate feeder space. Below is a table developed by Dr. Mike Brumm that describes the relationship between pig weight, shoulder width and individual feeder space requirements. Individual feeder space should be enough to allow a pig to freely eat but also be sufficient for other pigs to eat in their space at the same time. For example, if the feeder has 3 feeder spaces, ensure than 3 pigs can eat there at the same time. PIC recommends 15 inches for each single bunk space.

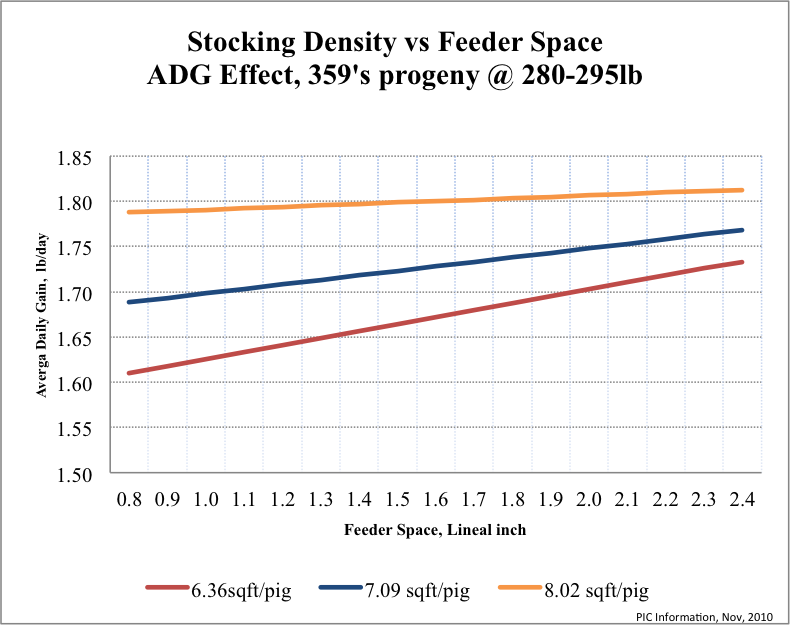

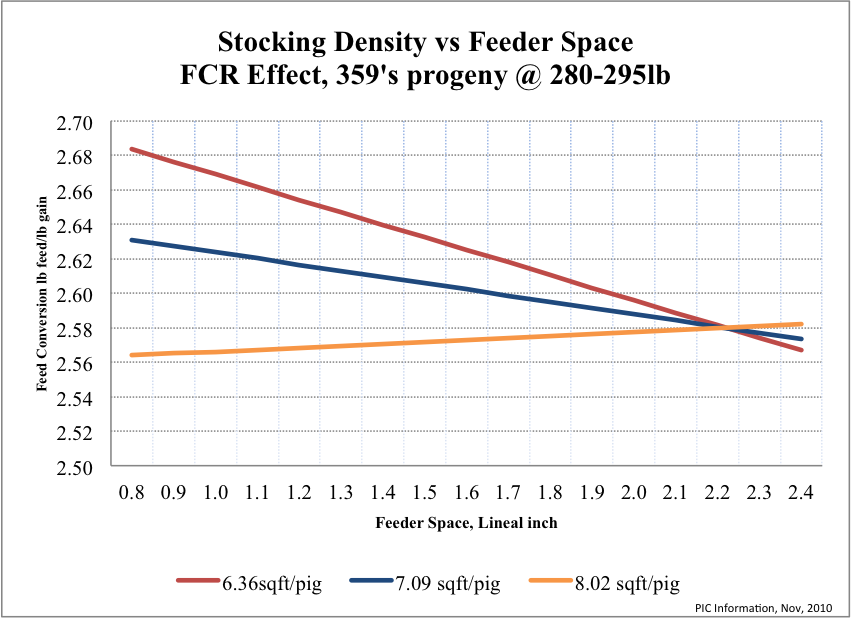

2-3) Linear Feeder Space and Stocking Density

The linear feeder space establishes how many pigs can be fed by a specific feeder. This measurement corresponds to the available inches of linear feeder space divided by the number of pigs per pen. In 2013, PIC conducted a study to understand the relationship between linear feeder space and stocking density. It was observed that the impact of linear feeder space on ADG and FCR was more important with higher stocking densities (6.36sqft /pig ) compared to pens with lower stocking densities (8.02 sqft/pig). However, in both cases the ADG and FCR were benefited by increasing feeder space. PIC recommends 8 pigs/dry feeder space (1.88-2 inch/pig ) and 12 pigs / wet-dry feeder space (1.25 inch/pig ).

4) Feeder Adjustment

There is a clear relationship between feeder adjustment, ADG and FCR. The more the feeder is adjusted towards the closed position, the FCR improves but ADG is reduced. This indicator defines how long a pig will use the feeder space. For example, if it is decided to work with 40% pan coverage and due to specific market reasons, there is a need to increase stocking density or market weight, each feeder will have higher feed demand therefore it could be of great help to increase pan coverage to reduce feeder competition.

5) Water Availability

Feed intake depends on water intake, so ensuring good water access is a critical factor. Four important points to consider (PIC recommendations): 1) Pigs per drinker (10 pigs/drinker) 2) Water flow (1 lt. /min in W2F barns) 3) Drinker height (nipples should be at shoulder level) 4) Water pressure (15-40 PSI). It is important to consider the additional water demands incurred when stocking density or market weight are increased or the energy level of the diet is reduced. In the case of wet-dry feeders, it is recommended to use auxiliary drinkers when room temperatures are above 85F and pig weight is above 180lb to reduce the competition for water in the feeder.

6) Energy Level of the Diet

It is well known that diet energy level can affect the amount of feed intake in pigs. Therefore, it is important to keep the farm team updated because feeder management can easily be modified to adjust to those energy changes. For example, feeder pan coverage should be increased when there is a reduction in diet energy level due to pigs increasing their feed intake demands and corresponding feeder usage time. Often farms operate at the maximum drinker/pig ratio (to reduce waste of water) and a change in the energy level can cause problems by increasing demand for water and not having enough access to drinkers.

7) Genetics

Different genetic lines have different feed intake habits. Such habits are characterized by; 1) amount of feed consumed per day 2) number of feeder visits per day and 3) feed consumption time per visit. For example, when we compare genetic lines with high ADG versus low ADG we see that there are differences in their feed intake and eating behavior. Low intake lines generally make more frequent visits to the feeder and consume smaller meals per feeder visit. Thus, it is good to understand the feed intake of your genetic lines so you can manage the feeder settings accordingly. Feeder settings can be adjusted more tightly for low intake lines whereas higher intake lines need more liberal feeder setting adjustments to give them more access to feed in the trough.

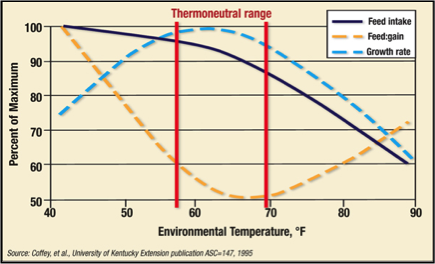

8) Temperature

The impact of environmental temperature on pig performance is well known. Increases in temperature will negatively impact ADG, due to reduced feed intake. Conversely, lower temperatures will produce an energy loss due to pigs trying to maintain body heat. In this situation, pigs will have a good feed intake but will not have the expected weight gain. Room temperature depends on facility design, weight of pigs and if there is a comfort zone for weaned pigs during the first weeks on feed (achieving 95F below brooders in the center of the mat and each pig has 0.4 sqft of mat space). The PIC Wean to Finish manual has various references about temperature curves under different production scenarios. Changes in stocking density or market weight can affect the ventilation needs in barns and if the ventilation equipment is not set to maintain adequate air exchanges rates, production losses will occur, therefore changes in marketing strategies can be helpful in this situation. The below graph is a good example on how environmental temperature affects ADG, FCR and Feed Intake (Coffey et al., 1995).