Do we manage pigs or space and time?

When breeding organizations create indices they are based on making the most profitable pig. This requires creating an economic model for profitability and it is almost always in terms of the pig including traits like born alive, growth rate, FCR, etc. Most commonly the focus has only been on the positives of performance while the negatives like sow or pig post-weaning mortality, levels of cannibalism, or prolapse have been ignored.

Is this the correct approach? From the point of view of selling to farmers, yes, as farmers always want to talk about the pig. How important are all of these metrics to the business and making money?

To understand this, we need to look at what are the limiting factors within the business. There are many business models within our industry from family-owned farrow to finish to corporate-owned contracted multi-site operations.

What do we sell? Ultimately as an industry, regardless of the business model, we sell kilograms (pounds) of pork, either on a live or carcass basis, We do not sell pigs….. If you look at pig price globally it is reported always in price per kg or lb or cwt either live or carcass. Never per pig. So, to maximize income first of all we need to maximize kg sold from our farms/systems.

What are the limiting factors? Time is the first limiting factor, there are 24 hours a day and 365 days per year. This is a limiting factor for all businesses.

The next limiting factor is space for growing pigs. Kilograms come from growing pigs after all. We grow pigs in farrowing, nursery, and finisher pens. On any closed farm or system, these spaces are truly a limiting factor. Even in systems that rely on contracting places, 99% of the time the reality is that space is limiting – there are not endless empty places waiting to be filled, and often the places contracted are paid by place, rather than pigs. For anyone buying pigs to grow/finish, space is of course also a limiting factor.

This makes 2 metrics possibly the most important in pig production when it comes to looking at maximizing sales volume – which is what we are all trying to achieve.

1, Piglets weaned per farrowing crate per year.

2, Kg(lb2) sold /m2(ft2) of Nursey and Finisher Space per Year.

These 2 metrics are very linked to maximizing kg sold/m2, the first major factor is filling the nursery with enough pigs (pigs weaned / crate)!

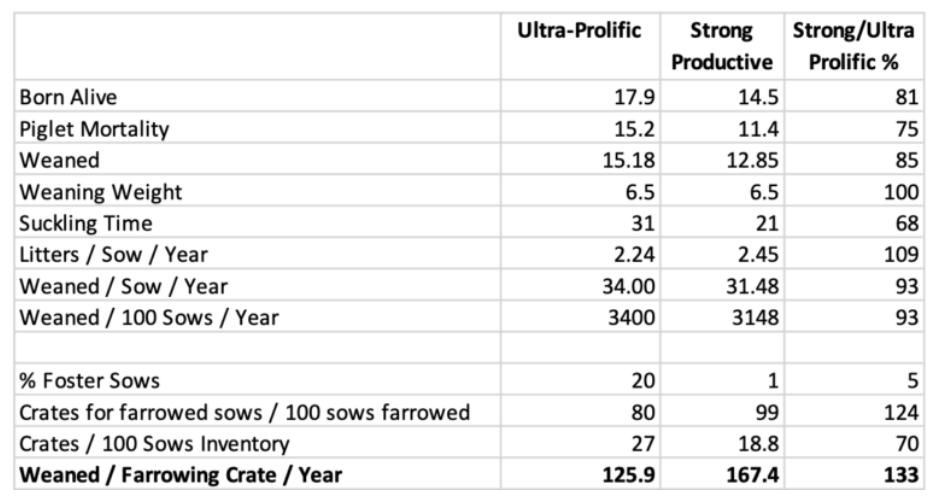

To analyze further for piglets weaned / farrowing crate/year. Let’s look at the 2 genetic types of sows available today:

- A very high born alive, European type requiring excellent management, foster sows, 28-day weaned piglets to get suitable weaning weights, and increasingly today milk systems in farrowing crates.

- Strong and productive sow, North American type, good born alive, easy and robust requiring little management. Able to wean at 21 days with no milk and minimal fostering

Looking at most metrics for “Ultra-prolific” sows most are better at a per sow level. However, there is a significant difference when it comes to looking at the effective use of the farm – the real limiting factor to profitability……. Strong productive sows able to wean large vigorous piglets at 21 days produce significantly more piglets per farrowing crate per year.

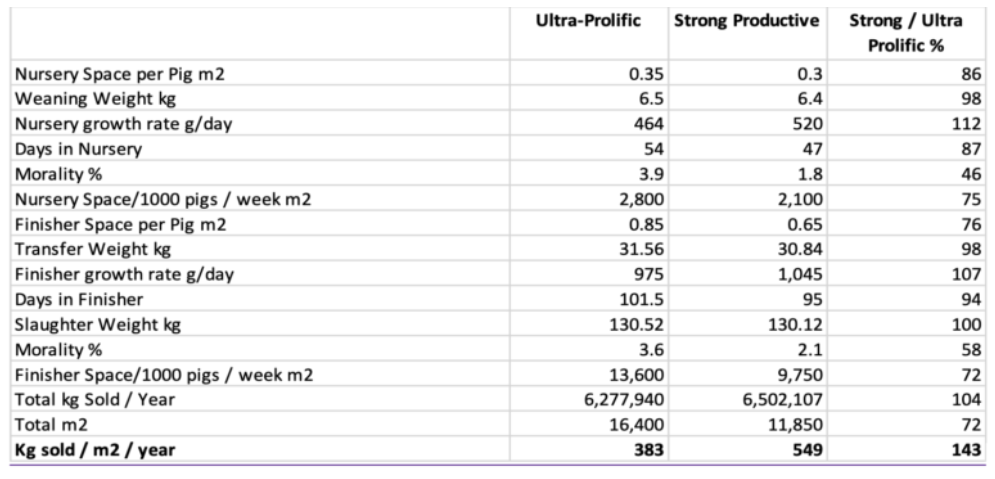

Looking at wean to finish performance, I have followed through with the type of pig the different type of sow produces, and recommendations for space, etc. for each type of genetics.

Once again, the robust fast-growing type of pig has a significant advantage when it comes to production from Nursery and Finisher floors!

The profit model!

Traditionally and with a good deal of common sense, we look at cost of production and profitability per kg. We do after all only sell kilograms!

So, in terms of maximizing output, Pigs/crate/yr and kg/m2/yr are key. These both have a big impact on cost as in pig production there is really only one variable cost, finisher feed. To explain if we reduce the sales weight of a pig by 1kg, what cost do we save – just finisher feed. All other costs remain the same.

This means for a full profit model there is a 3rd important metric. That is margin over (finisher) feed. So, the full profit model looks at:

1, Piglets weaned/crate/year.

2, Kg(lb)sold/m2(lb2)/ year.

3, Margin over finisher feed cost.

Going further, what if we were to switch the model from looking at cost and profit per kg(lb) of pig to looking at it at the farm level, that is based upon the limiting factor for the farm, space, and time. Many other businesses do manage space and time, retail and transport are just 2 examples.

What if we were to look at profit per farrowing crate per year, or profit per m2 of nursery and finisher space. The numbers suggest it could have a significant change in perception of what really matters.