Development and use of sow cooling pads during farrowing & lactation

Sows under heat stress have reduced milk production and litter weight gainEditor's note: this article is part of the resources found on the Purdue University Pork Archive Page.

Heat stress has negative effects on sow productivity and reproductive performance. It has multiple impacts on animal metabolism and physiology. These include: increased body core temperature, homeorhetic adaptations that increase blood flow to the skin to dissipate radiant heat, increased respiration rates to remove the excess heat, and reduced feed intake as a strategy to reduce heat production. Consequently, sows under heat stress have reduced milk production and litter weight gain. Sows with excessive body protein loss during lactation have increased days from weaning to estrus and reduced conception rates.

During the last three decades, continuous selection for increased litter size and milk production has increased the heat production of sows and reduced their upper critical temperature. This selection has also resulted in decreased piglet birth weights and less body energy reserves at birth, requiring greater farrowing room temperatures and the use of heat pads or heat lamps to provide local heat for piglets. Daily feed intake, milk production level, and subsequent reproductive performance of sows are limited by the need to have higher room temperatures for increased piglet survival. If the anticipated environmental warming continues to adversely affect ambient temperatures, it will become more important that lactating sows be provided with some form of active cooling to maintain productivity and animal welfare.

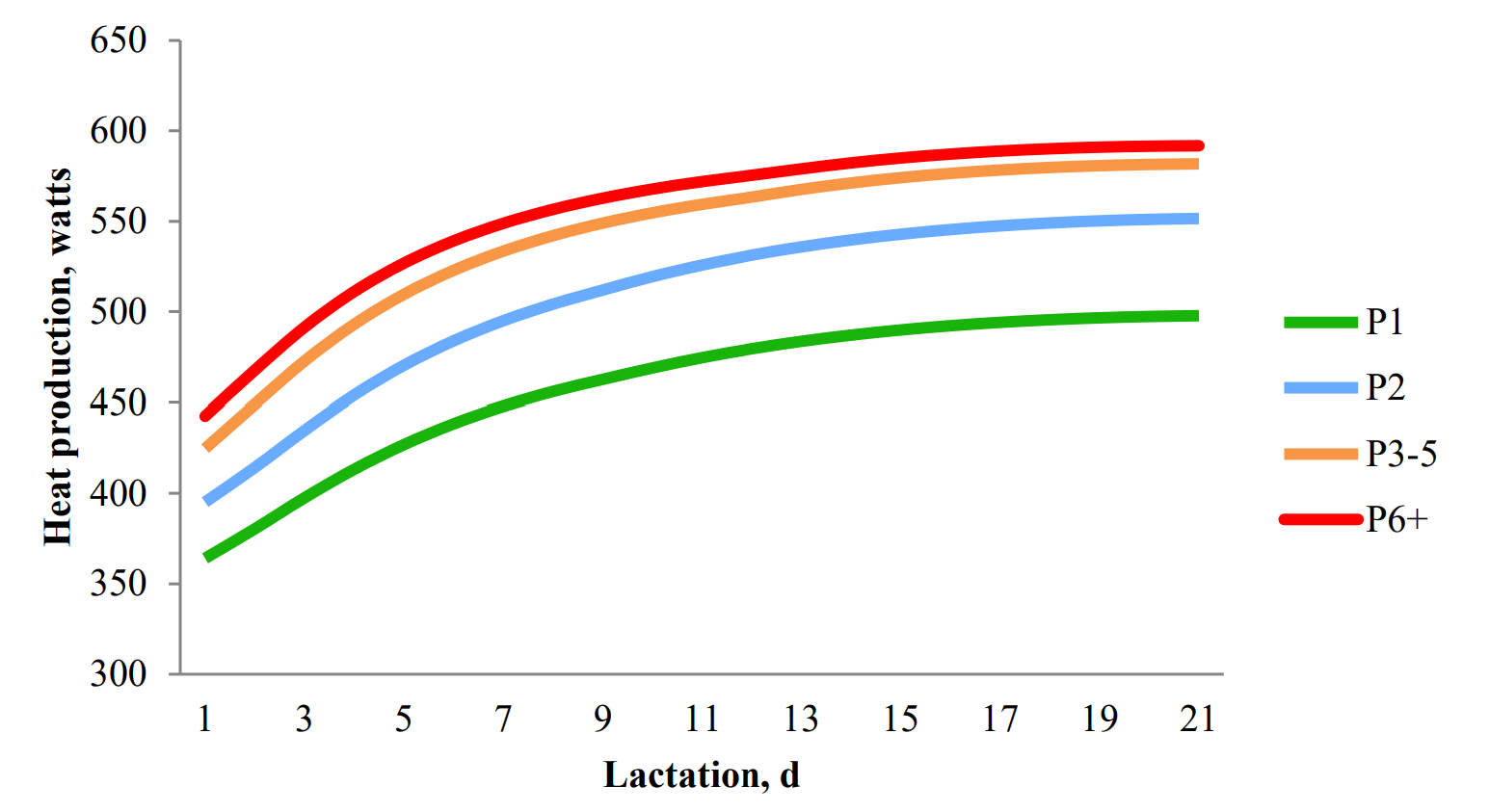

The Animal Sciences and Agricultural Biological Engineering Departments at Purdue University and the USDA-ARS Livestock Behavior Research Unit have been working together for the last three years to develop a cooling pad able to locally and efficiently remove the excess of heat from lactating sows. Initial studies were focused to estimate the daily heat production of lactating sows. A heat production model was developed using the energy efficiency equations from NRC, (2012). The model estimates the heat production of sows with different daily feed intake and milk production levels during lactation, and a summary of those results is shown in Figure 1. A lactating sow produces between approximately 350 to 600 watts of heat as a daily average, and heat production increases as the parity and lactation progresses. Heat stress results when the heat energy produced by the animal is greater than the dissipated amount. Floor cooling provides an animal with supplemental cooling during periods of heat stress.

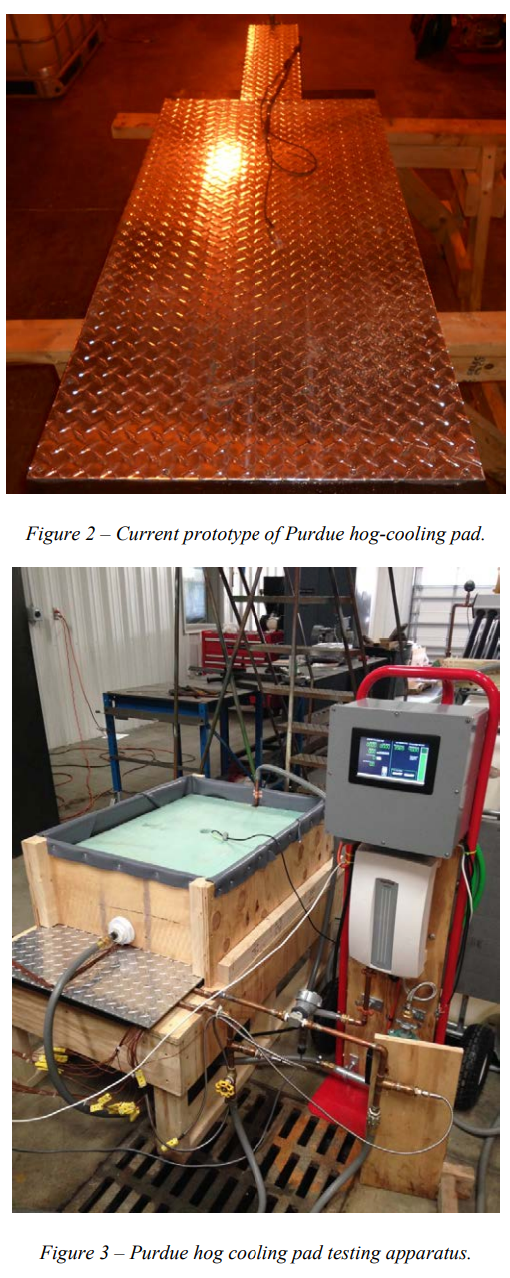

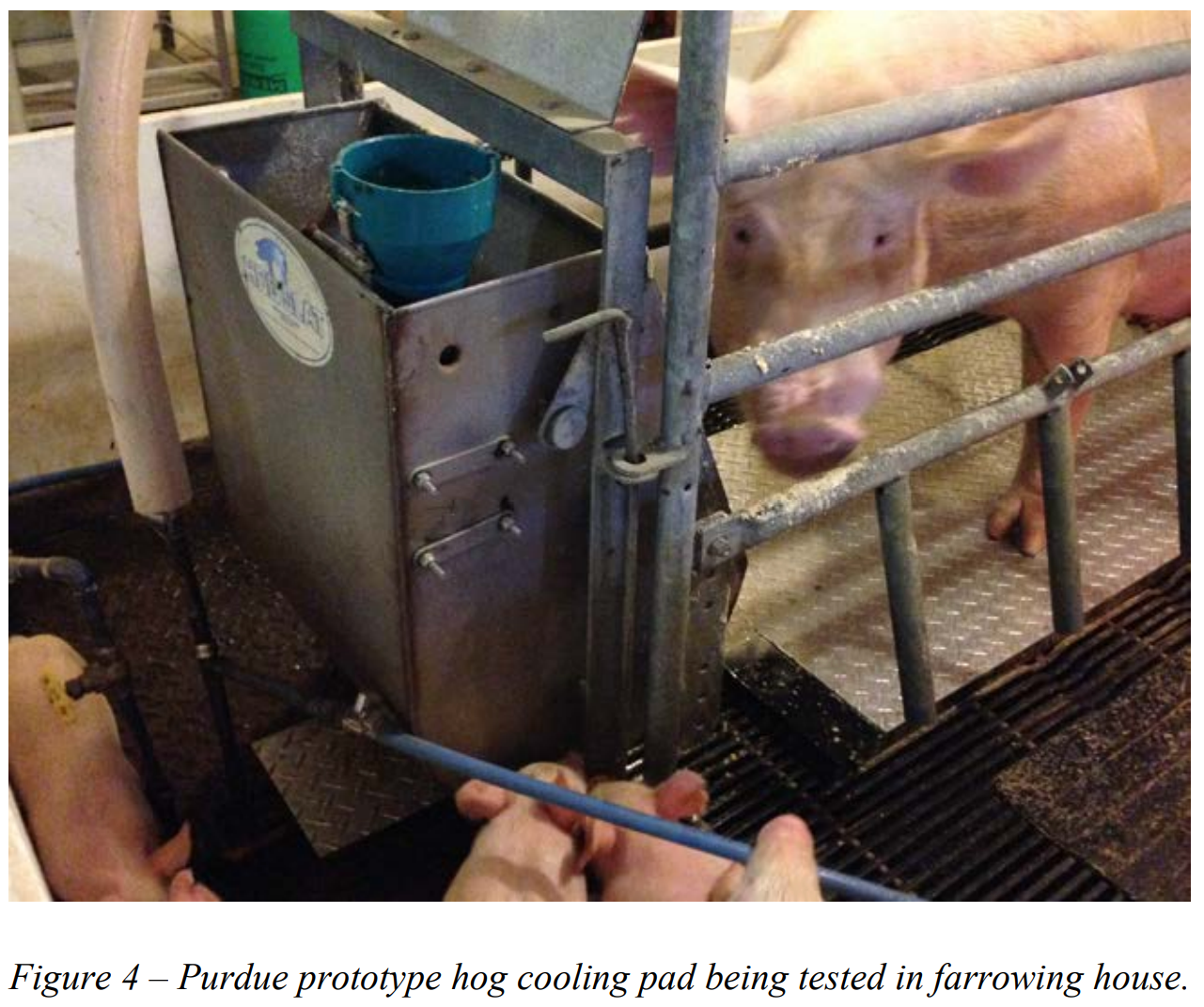

Floor cooling is based on the conduction of heat from the source (the animal) to a sink (chilled water running through the pipes), while the animal is lying down. Thermodynamic laws govern the rate of heat transfer through temperature differentials. The design and the materials used in the cooling pads were selected in order to facilitate heat removal. Aluminum and copper have a low heat capacity and high thermal conductivity, which means that rather than storing the heat, they are able to effectively transfer heat between the two temperatures. The cooling pad has been built with a heavy duty aluminum plate in the surface, high-density polyethylene base and copper water pipes attached to the aluminum plate. The current prototype, shown in Figure 2, removes approximately 50% more heat than the previous model. All heat transfer tests have been performed using an “artificial sow”, which is a bag with approximately 40 gallons of water heated at 40º C, shown in Figure 3. The initial test units had numerous thermocouples and were run through heat transfer trials with different cooling water flow options, including constant cool water flow, set times between cool water flushes and alternative pad temperatures to initiate the cool water flush. From these initial tests, pad dimensions were enlarged, and the range of constant flow rates, time between flushes and desired upper set temperatures for different environmental conditions were refined.

The refined cooling pad designs have been used in sow lactation trials, shown in Figure 4. One of the trials was performed under severe heat stress conditions (35 º C and 69% RH) to test the cooling effect on behavior and heat stress markers in sows (respiration rate and skin, rectal and vaginal temperatures). Sows with no cooling spent more time in a “dog like posture” to increase body heat dissipation to the environment, less time on the feeder and lesstime milking in comparison to the sows with an active cooling of 0.85 L/min. After 80 min of cooling, sows with active cooling had lower respiration rates (45 versus 122 breaths/min), heart rates (100 versus 119 beats/min), vaginal temperature (39.2 versus 40.1ºC), rectal temperature (39.0 versus 40.0ºC) and skin temperature (38.6 versus 39.4 ºC) than sows with no active cooling, respectively. The heat removal rate was three to four times greater than previous cooling pad designs made of concrete and steel pipes, covering entire floor sections.

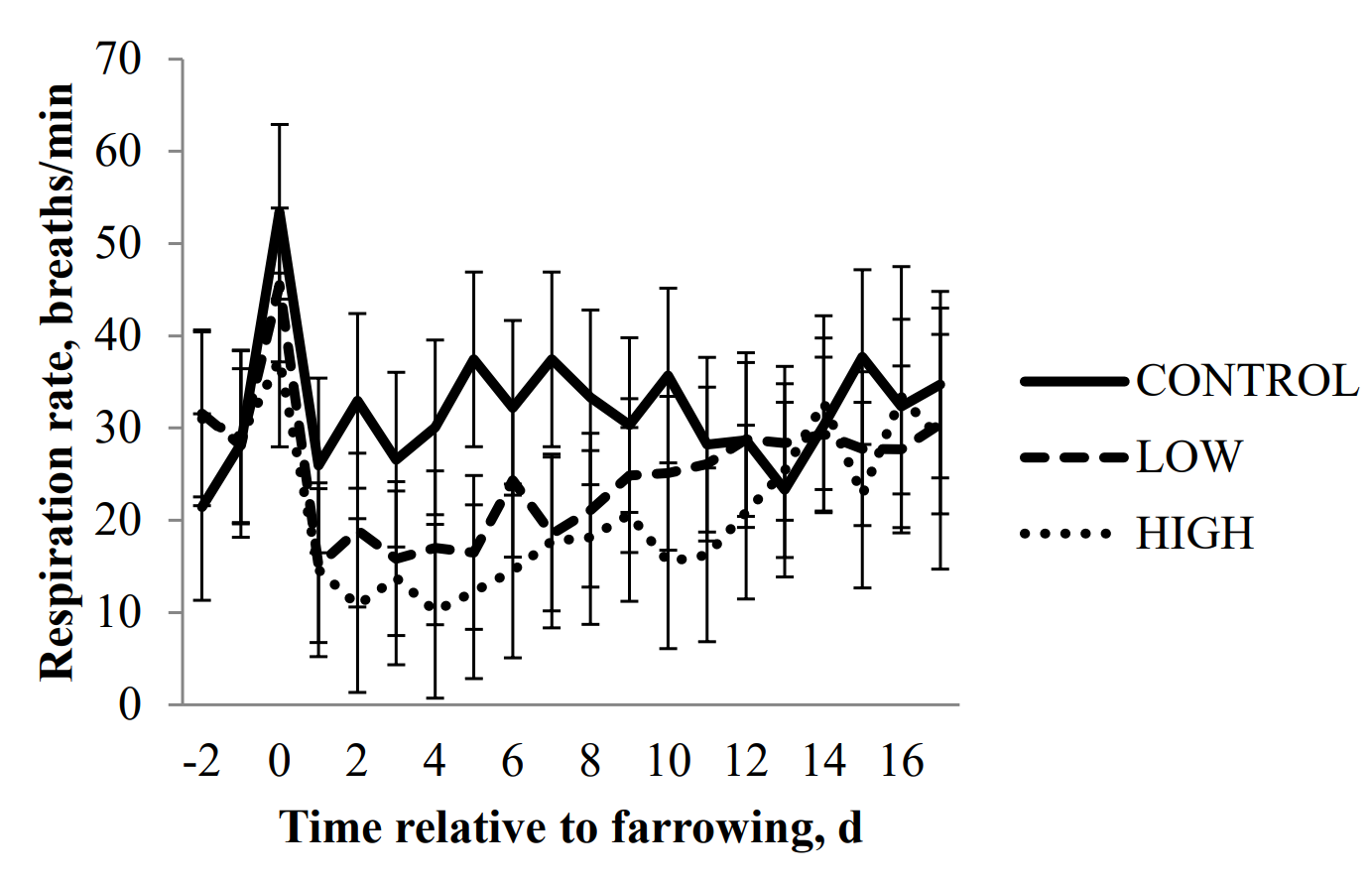

The effectiveness of the sow cooling pads for an entire lactation was evaluated under mild and moderate heat stress conditions. The moderate heat stress room was targeted to achieve 32ºC from 0800-1600 h and 27ºC for the rest of the 24-hour day. The mild heat stress room was targeted to achieve 27ºC and 22ºC for the same periods, respectively. Yorkshire-Landrace sows were blocked by parity and BW, and assigned to two farrowing rooms which differed only in environmental temperature. Each sow was provided an eight–row cooling pad. Sows received either a constant cool water flow of 0.00 L/min (CONTROL, n = 9), 0.25 L/min (LOW, n = 12), or 0.50 (HIGH, n = 10) L/min.

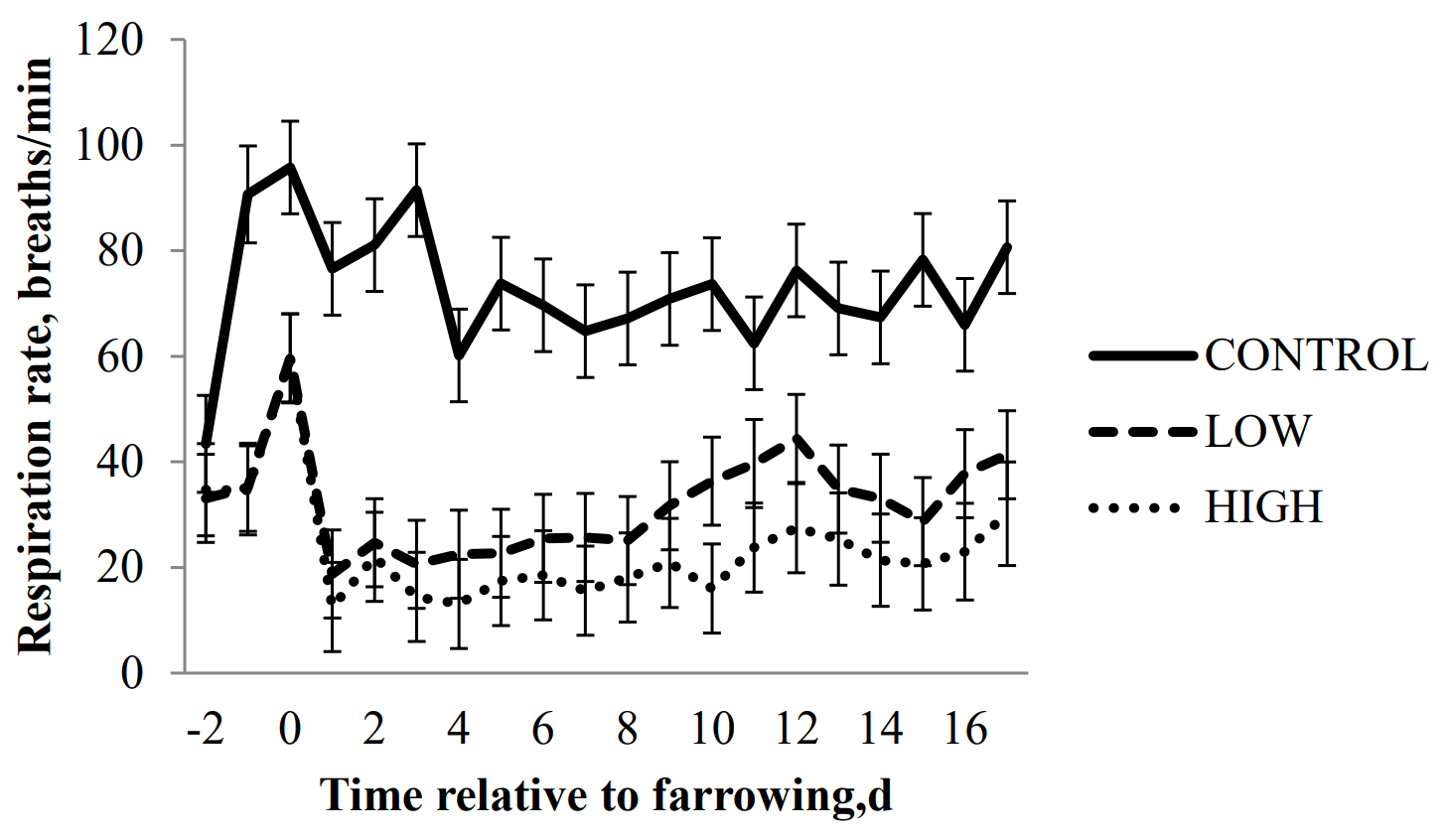

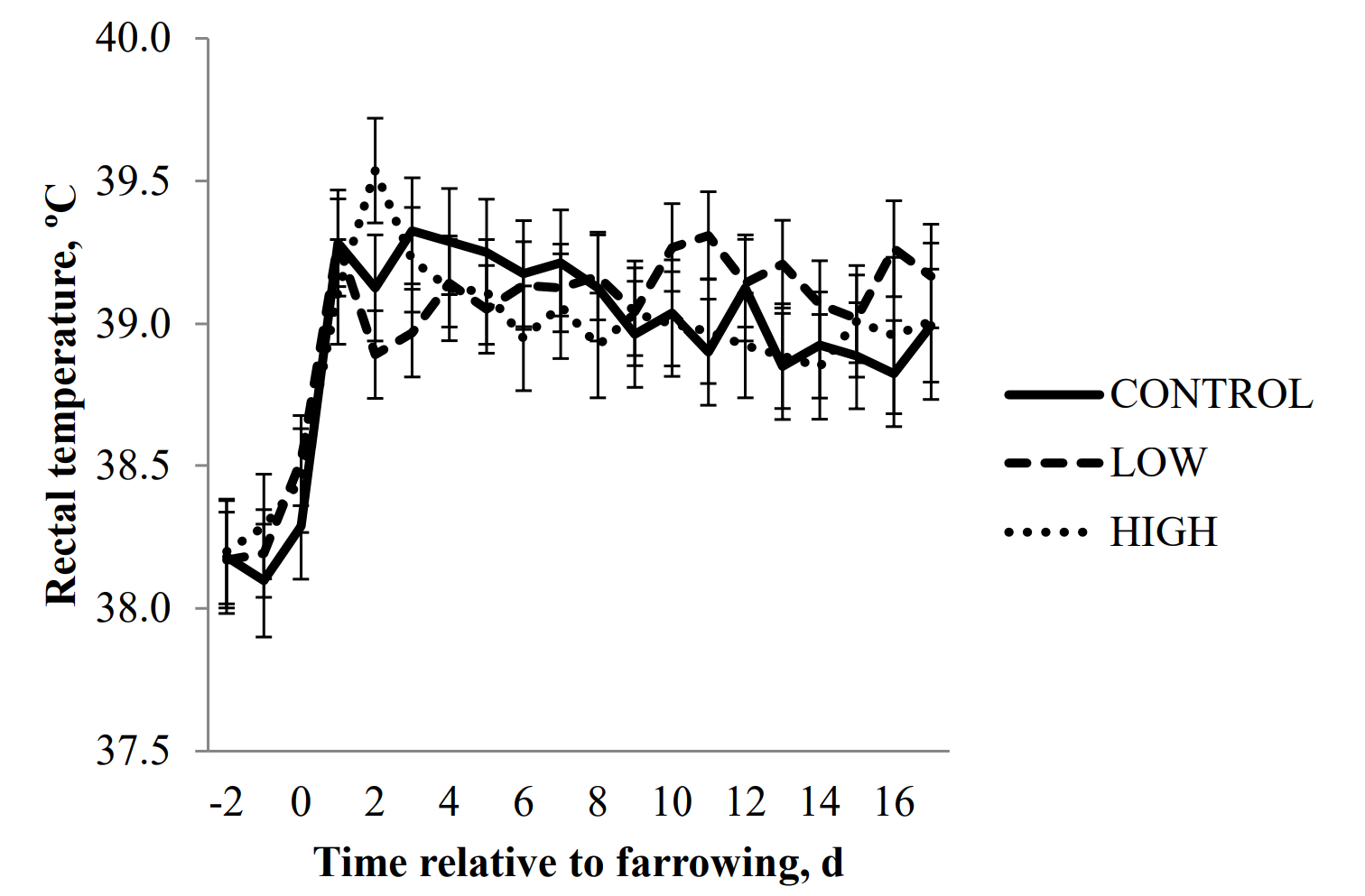

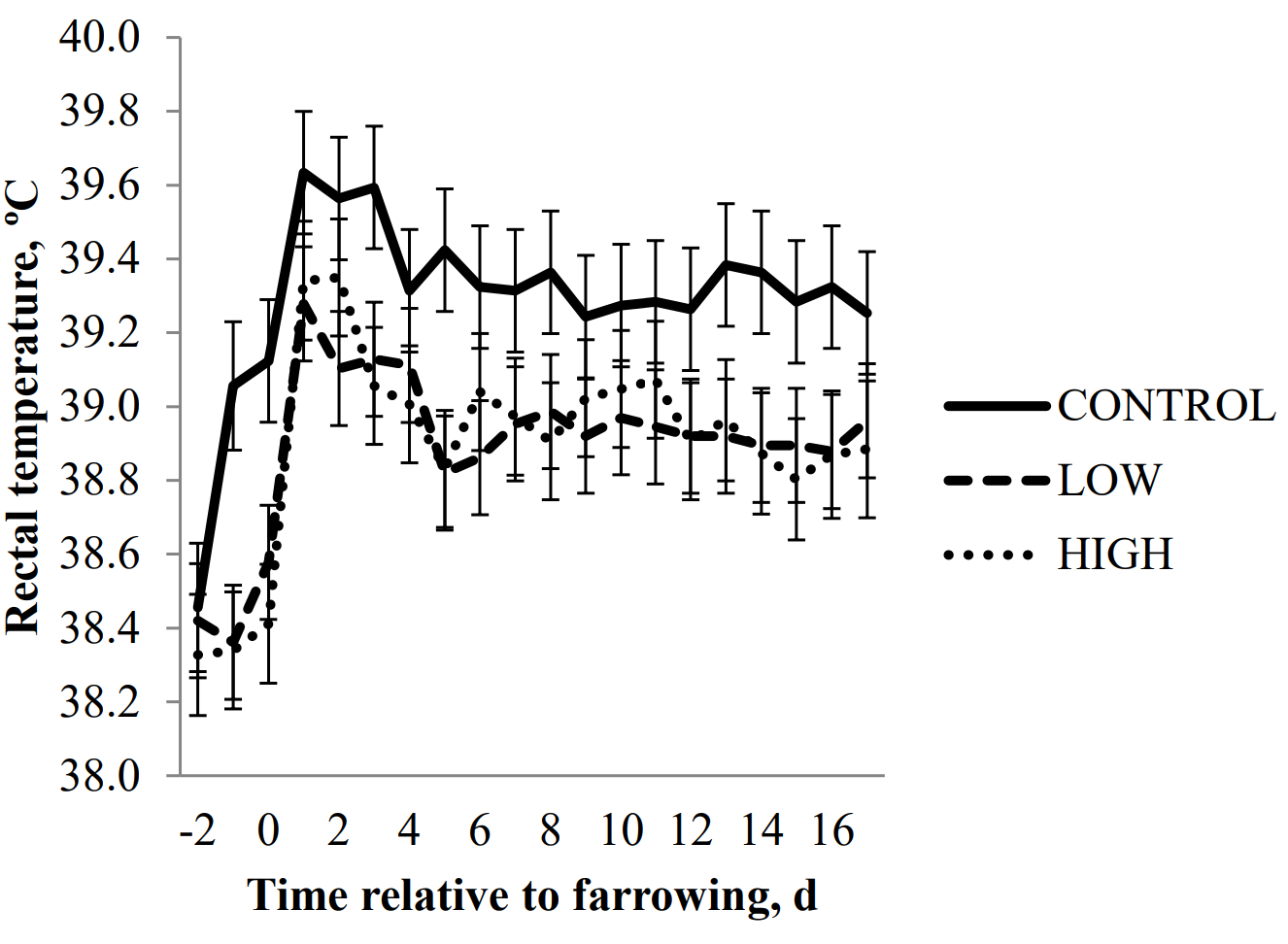

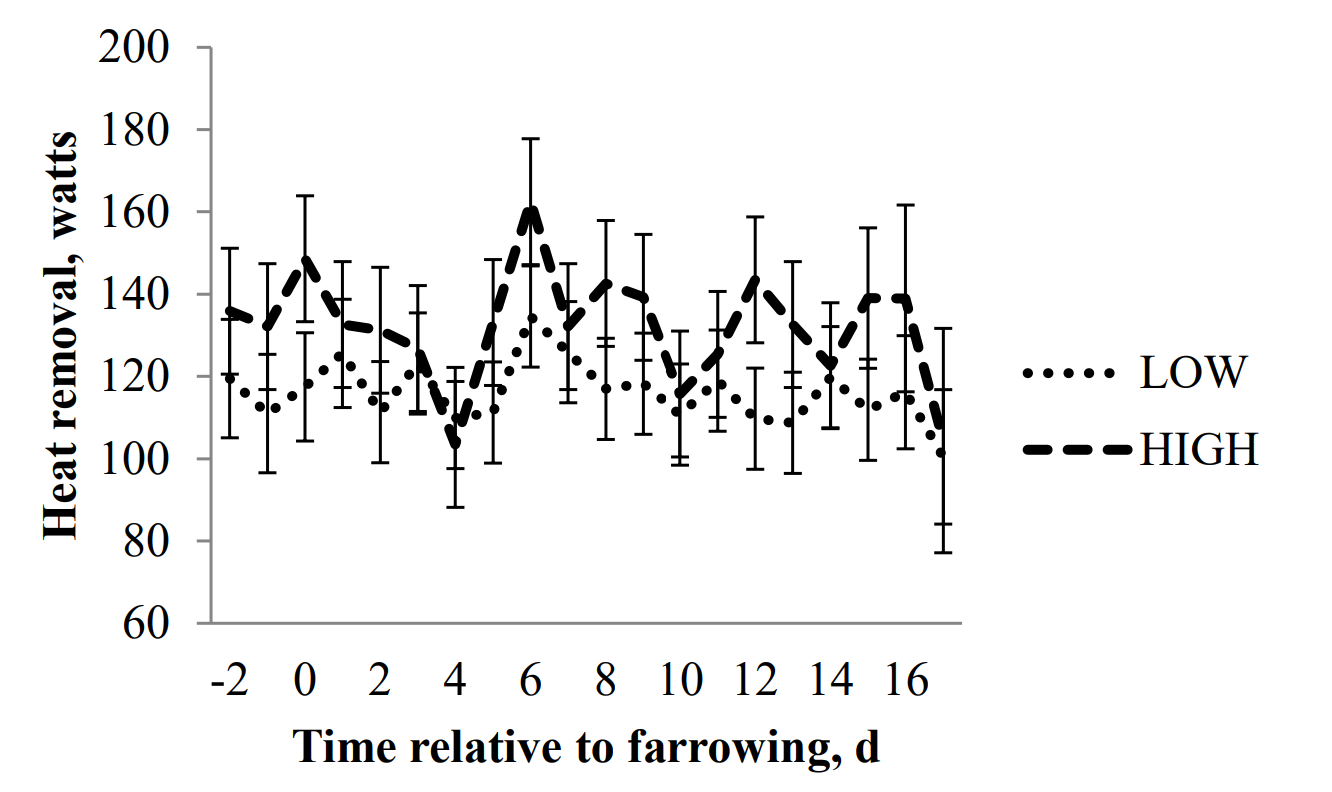

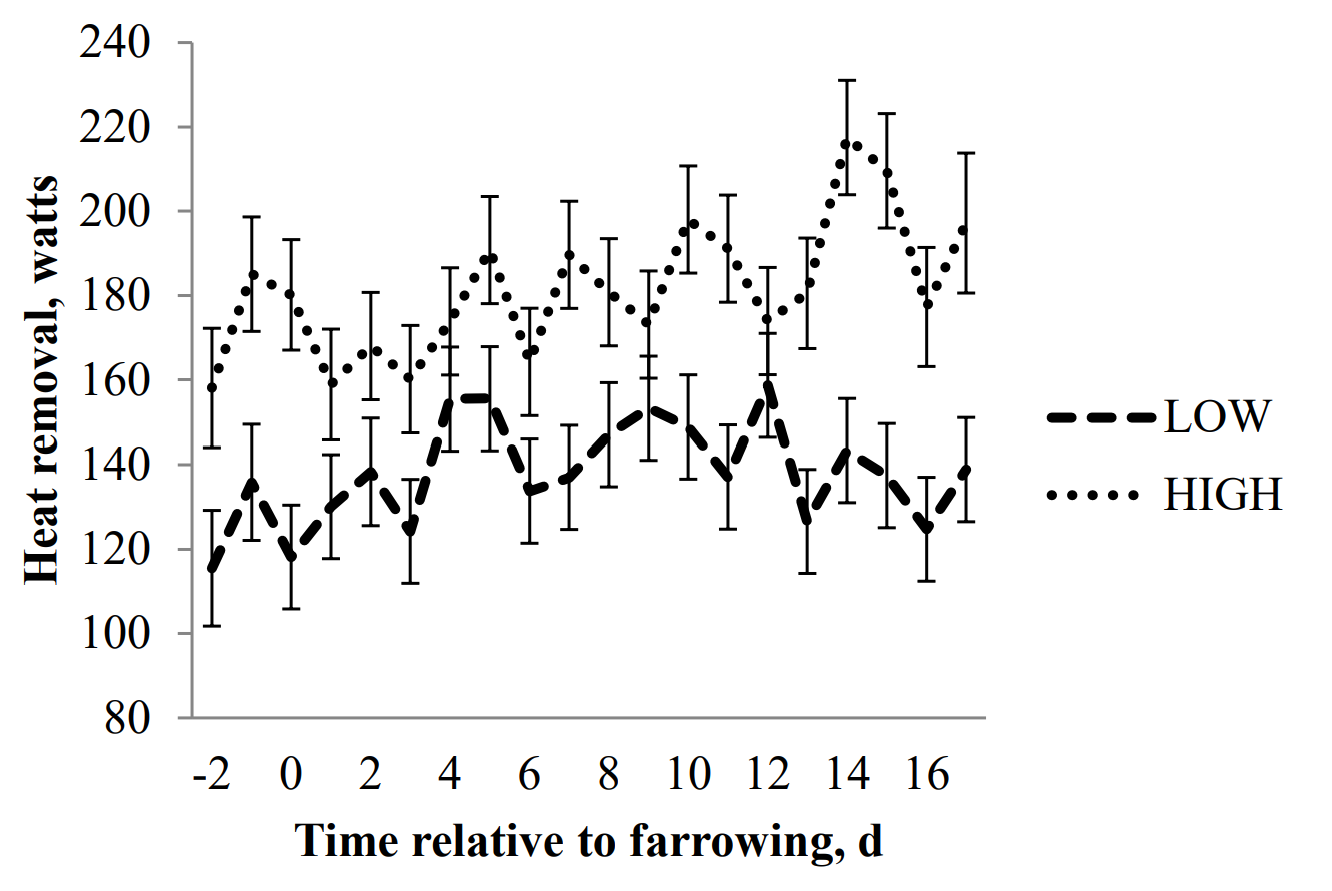

Water inlet and outlet temperatures and flow rates were recorded to estimate heat removal. Respiration rates (RR), rectal temperatures (RT) and skin temperatures (ST) were recorded daily (0700 and 1500 h) from the second day in the farrowing room to weaning at a mean age of 19 days. The sow RR, ST, RT and estimated heat removal were affected (P < 0.036) by pad treatment (PT), time of day, room temperature (RTEMP), day of lactation, PT×RTEMP, PT × time of day, time of day × RTEMP, day of lactation × PT, and 3-way interaction of PT × RTEMP × time of day. The RR of CONTROL sows were 23, 56, 41,and 89, LOW sows were 21, 24, 29, and 41, and HIGH sows were 18, 20, 24, and 27 breaths/min and increased (P < 0.001) as heat stress increased from mild 0700 h (22ºC), moderate 0700 h (27ºC), mild 1500 h (27ºC), and moderate 1500 h (32ºC). The ST of LOW sows were 1.1 0.6, 0.8, and 0.4 and ST of the HIGH sows were 1.7, 0.7, 1.1, and 1.0ºC less (P < 0.01) than CONTROL sows for the same heat stress conditions (mild 0700, moderate 0700 h, mild 1500 h and moderate 1500 h, respectively). The RT of LOW sows were 0.02, 0.20, 0.11, and 0.58ºC and HIGH sows were 0.04, 0.22, 0.02, and 0.57ºC less than CONTROL (P < 0.04) for the same four treatments. The difference in heat removal between the HIGH and LOW flow rates was 16 watts (132.1 versus 116.1) in the low heat stress rooms, but increased to 43.4 watts in the moderate heat stress rooms (181.4 versus 138.0, (P = 0.048 for RTEMP × PT). The sow cooling pads statistically reduced the measures of heat stress. The results indicated that the LOW flow rate was adequate for the mild heat stress room and the HIGH flow rate was needed for the moderate heat stress rooms. Figures 5 and 6 show the effect of the Purdue hog cooling pads on RR, while Figures 7 and 8 show the effect on RT. Figures 9 and 10 displays the energy transfer away from the animal through the cooling pad with varying coolant flow rates.

For widespread implementation and use of this technology, key decision makers in the pork industry will need to be shown data estimating the direct and indirect economic returns of cooling pad operation in different environmental conditions. Long-term studies are being planned for commercial barns to estimate the direct and indirect effects of heat stress, and the benefits on sows’ lactation and reproductive performance of cooling pad technology operation. In the near future, the use of cooling pads will be investigated on boars, growing finish pigs, and gestating sows.