Biosecurity hazards in pig transport

Staged loading may reduce the frequency of pathogen transfer during pig transportDerald Holtkamp, DVM, Iowa State University, said that outbreaks

in grow/finish herds can have significant impacts economically and serve as a

source of virus for breeding herds. One event that has the potential to

introduce viruses into growing pigs is the transport of pigs to market.

In the United States, a group of pigs is typically transported to market over several weeks, creating the opportunity for pigs remaining at the farm to become infected after the first loads are removed from the barn. The pigs remaining in the group are then subject to production losses and become a potential source of virus for other swine farms, Holtkamp said during the 2022 Leman Conference.

Previous research has demonstrated that livestock trailers are frequently contaminated after transporting pigs to swine slaughter plants, he said. Washing and decontaminating trailers between loads can mitigate the contamination when it occurs, but not all trailers are washed between every load of market pigs, and when trailers are washed, mitigation is not guaranteed, he added.

Therefore, when livestock trailers return from a swine slaughter plant and enter growing pig sites to load market pigs, they may remain contaminated with infectious swine pathogens. For pigs remaining in the barn to become infected during loading, viral contamination must be transferred from the livestock trailer to the pigs, he explained.

Staged loading

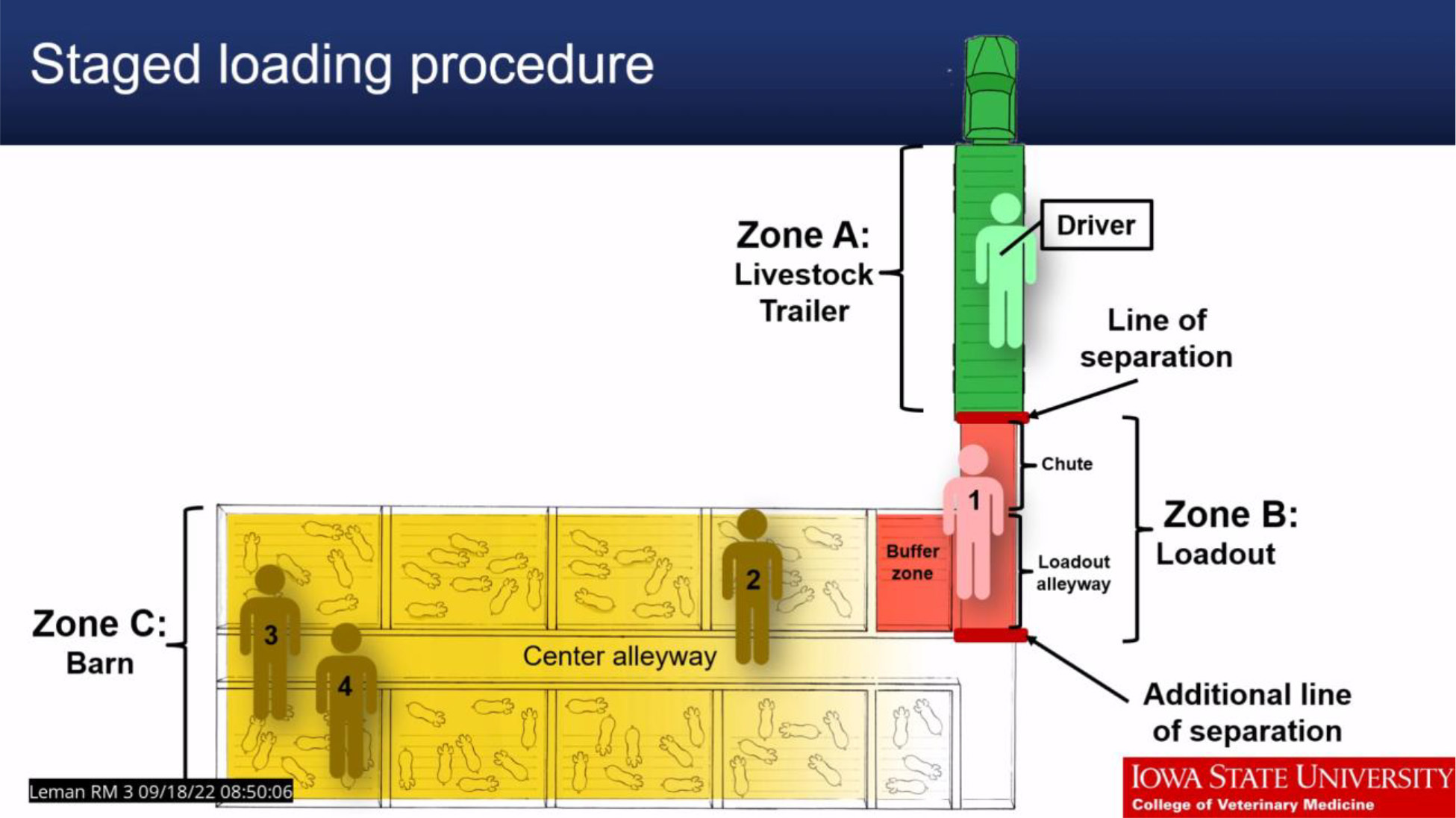

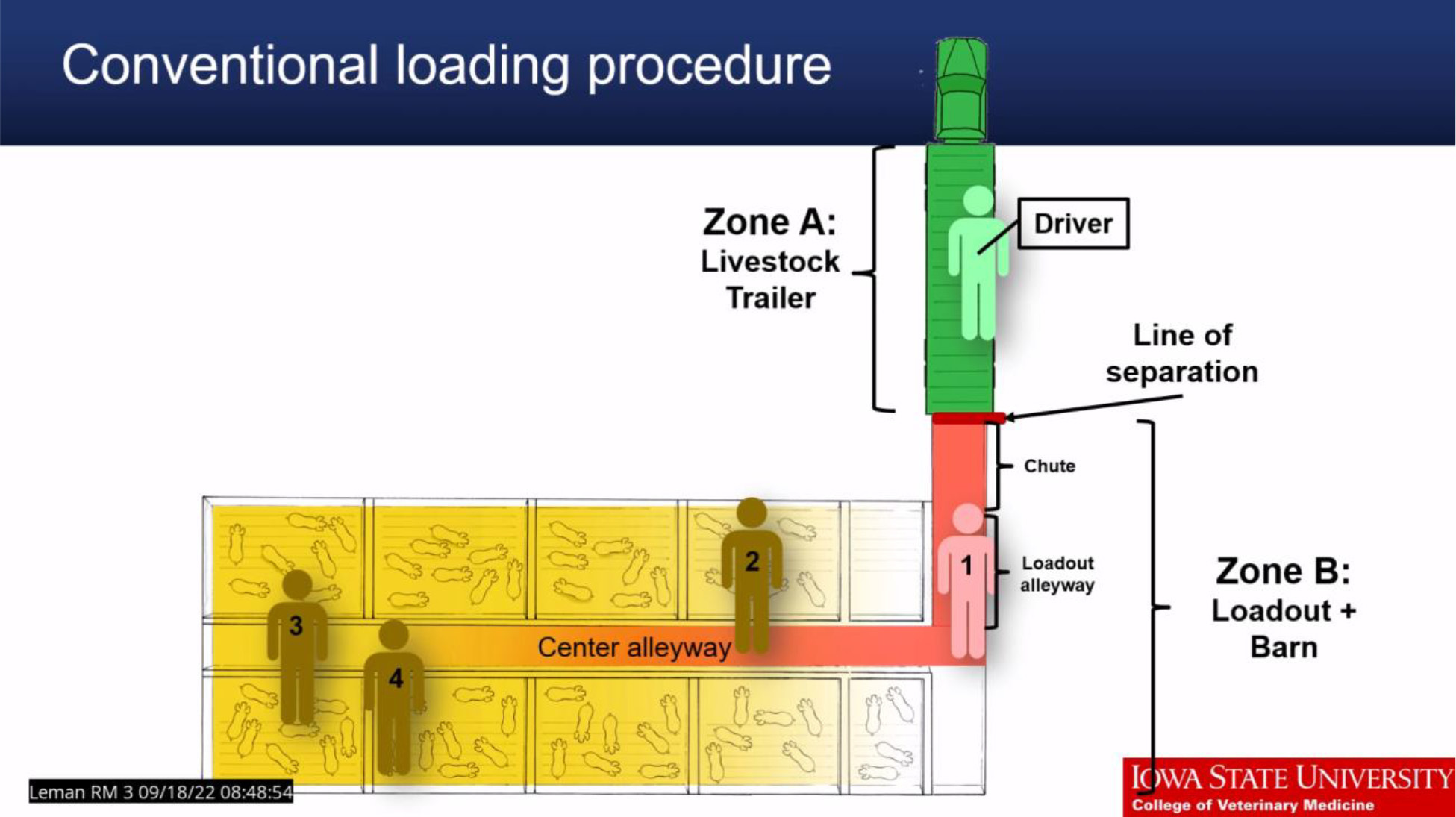

Staged loading may reduce the frequency of the transfer of pathogens; however, it has not been studied, he said. Staged loading involves creating an area between two lines of separation where the entire load or small groups of pigs can be “staged” before loading, Holtkamp said.

He noted that the loadout alleyway may be used as the staging area where the first line of separation is positioned where the trailer contacts the chute, and the second line is where the loadout alleyway and the barn alleyway intersect.

Holtkamp and colleagues at Iowa State performed a study to evaluate the effectiveness of a staged loading procedure when loading market pigs for reducing the transfer of contaminants from livestock trailers to the barn.

A controlled trial compared a conventional loading procedure to a staged loading procedure, with 10 replicates per loading procedure, he said.

In the staged loading procedure, one member from the loadout crew was stationed in the loadout alleyway between two lines of separation, Holtkamp said.

Two-hundred sixteen grams of dry fluorescent powder (Glo Germ, Glo Germ Company, Moab, UT) was mixed with approximately 0.5 liters of obstetrical (OB) lube and 0.25 kg of dry wood shavings in a large zip-lock plastic bag and spread evenly on the livestock trailer floor, just inside the roll-up door that opens to the chute, Holtkamp explained.

Each loadout was observed, and when completed, Glo Germ contamination was evaluated using a 120 x 55 cm2 grid that was divided into 264 5 x 5 cm squares at eight different measuring points; one in the chute, two in the loadout alleyway, and five in the center alleyway of the barn, he said.

Holtkamp noted that under the conditions of the study, the staged loading procedure reduced the transfer of Glo Germ from the livestock trailer to the barn. Four out of the five measuring points in the center alleyway of the barn had a level of contamination that measured significantly lower (p<0.05) for the staged loading protocol compared to the conventional loading protocol, he concluded.