Investigating and Mitigating the Causes of Foam Accumulation on Swine Manure Deep Pits

Manure pits that foam are more biologically active and have a lower content of volatile fatty acids and a higher rate of methane production than non-foaming pits, report Daniel Andersen and others in the Iowa State University Animal Industry Report 2014.Summary and Implications

The appearance of foam on the surface of deep-pit swine manure storage is a serious concern for the pork industry. Manure foam has the capacity to trap gases produced by the anaerobic decomposition of the manure, leading to dangerous flammable gas concentrations upon foam disruption.

Field sampling and feeding trials were conducted to determine manure characteristics leading to foam accumulation.

Results indicated that foaming pits were more biologically active having lower volatile fatty acid contents and higher rates of methane production. Research is being undertaken to develop foam mitigation strategies based on these findings.

Introduction

Biological foam accumulation poses a number of challenges that must be addressed from a managerial and safety standpoint.

Foam accumulation can significantly reduce the amount of storage available in deep pits, stressing the pumping cycle and forcing the producer to apply manure during untimely seasonal conditions. Foam results from the accumulation of flammable gases (most significantly methane) produced by the anaerobic decomposition of the manure being captured on the manure surface. Depending on the amount of gas that is trapped in a given barn, dangerous gas concentrations are possible during a sudden breakage of foam. This can result in flash fires if a spark is present.

Developing successful foam mitigation and remediation strategies requires an understanding of differences in physical, chemical, and biological characteristics of manures from foaming and non-foaming manure pits. Thus the objective of this study was to evaluate differences in manure characteristics between these pits and to evaluate the impact of dietary feedstuffs on manure properties.

Materials and Methods

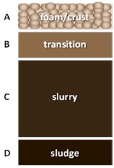

Monthly manure sampling was conducted at 60 swine finishing facilities with deep pit manure storages having various manure surface conditions (foaming, crusted, liquid). At each site, samples were extracted from multiple depths (schematic of sampling strata in Figure 1) and the amount of foam, depth of manure, and temperature of the manure was measured.

After collection samples were analysed for key characteristics expected to be related to foam accumulation including methane production rates, surface tension, short and long chain fatty acid content, foaming capacity and stability, total and volatile solids content and pH.

In addition to field sampling, dietary studies were conducted to evaluate the impact of different feeding strategies on foam accumulation potential. Two dietary studies have been conducted; these included the impact of protein level and source on manure foaming properties as well as impact of carbohydrate source. In each study 48 pigs were randomly assigned to one of the treatment diets. Pigs received ad libitum feed containing its assigned diets. Manure from each animal was collected twice a day and stored in a dedicated storage tank. At the conclusion of the dietary trial manure samples were collected and analysed for the same parameters as field samples.

Results and Discussion

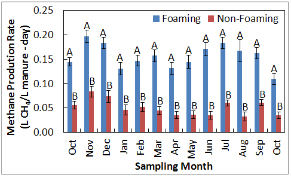

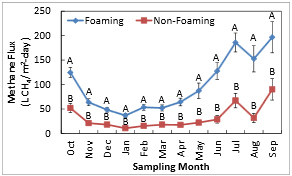

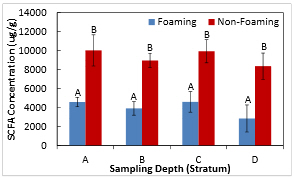

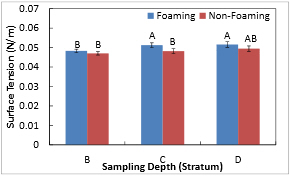

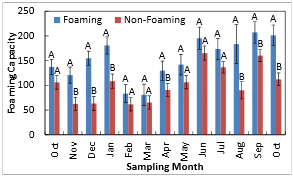

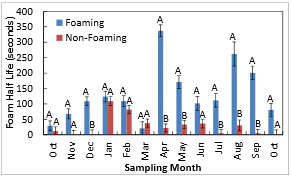

Results indicated that manures from foaming pits were more biologically active than non-foaming pits, having significantly higher methane production rates and methane fluxes (α=0.05; Figures 2 and 3). The results also indicated manures from foaming pits had significantly lower short chain fatty acid contents (α=0.05), presumably due to faster processing and conversion to methane. Surface tension data tended to indicate that manure from non-foaming pits had lower surface tension than from foaming pits, especially at lower levels in the pit. This could potentially be related to reduced bubble stability in the non-foaming manures.

Finally, results indicated an accumulation of long-chain free fatty acids in the foam, but its relationship to manure foaming capacity has not been confirmed.

None of the diets studied has resulted in stable foam develop but they have provided insight into differences in solids contents, methane production potential, surface tension and foaming capacity as a result of different feed components.

Future work will be conducted to confirm these differences and to test mitigation strategies related to these findings.

(Error bars represent the standard error of the mean. Different letters within a month represent significant differences at α=0.05)

(Error bars represent the standard error of the mean. Different letters within a month represent significant differences at α=0.05)

(Error bars represent the standard error of the mean. Different letters represent significant differences at α=0.05)

(Error bars represent the standard error of the mean. Means not connected with the same letter are significantly different at α=0.05)

(Error bars represent the standard error of the mean. Different letters within a month represent significant differences at α=0.10)

(Error bars represent the standard error of the mean. Different letters within a month represent significant differences at α=0.10)

The authors of this paper were Daniel Andersen (Assistant Professor, ABE), Kurt Rosentrater (Assistant Professor, ABE), Brian Kerr (swine nutritionist, USDA-ARS;) and Steve Trabue (research chemist, USDA-ARS).

Acknowledgements: The authors gratefully appreciate funding from the Iowa Pork Producers Association and the swine integrators who allowed monthly sampling at their operations.Thank you to the National Pork Board’s Pork Checkoff programme for funding this research.

April 2014