Big Dutchman Innovation Sets New Hygiene Standards for the Feeding of Suckling Pigs

GERMANY - Big Dutchman has enhanced the well-known CulinaCup system for the feeding of suckling pigs and developed an automatic feeding system.

CulinaFlex successfully disables pathogens in the feeding of suckling pigs

With CulinaFlex, the pig equipment supplier from Vechta sets new hygiene standards. The innovation eliminates impurities and fresh air from the feed drop pipes, thus removing two of the main causes of pathogen formation in piglet rearing.

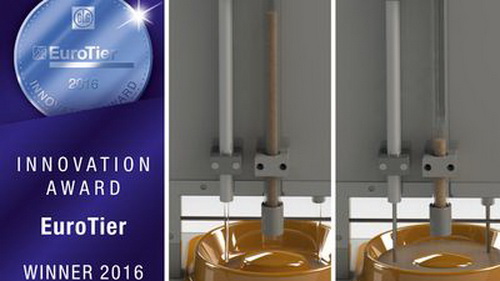

In addition to improving piglet health, the valve also has positive effects on labour efficiency because the pipes no longer require any cleaning. An international expert commission of the “DLG” (German Agricultural Society) announced an innovation award for CulinaFlex.

The central part of the system is a pinch valve installed in the drop pipe. This valve functions similarly to a balloon: In contrast to currently available drop pipes, CulinaFlex squeezes all remaining feed from the pipe when it is emptied. The balloon function also displaces the oxygen to create an anaerobic environment. The result: The feed that reaches the feed pan does not contain any germs.

Not just the piglets, but also the producers benefit from CulinaFlex. As cleaning is not necessary, farmers save up to 1.5 hours of work annually per valve.

The CulinaCupLine was originally devised by the feed producer Bröring, located in Dinklage. Today, Big Dutchman distributes and further develops the system. The two companies have started to cooperate in the development and distribution of systems for the feeding of suckling pigs.